slippers-on

Music...let it move you!

http://www.huffingtonpost.com/ben-e...medium=referral&utm_campaign=zergnet_1060901&

This post was co-authored with Avery Louie.

It’s nearly impossible to be on a train, fly on a plane or walk down the street without spotting the iconic “b” logo. Beats has been extremely successful in marketing its headphones and now enjoys large market appeal. But with a sky-high retail price of $199, is there more to Beats than meets the eye?

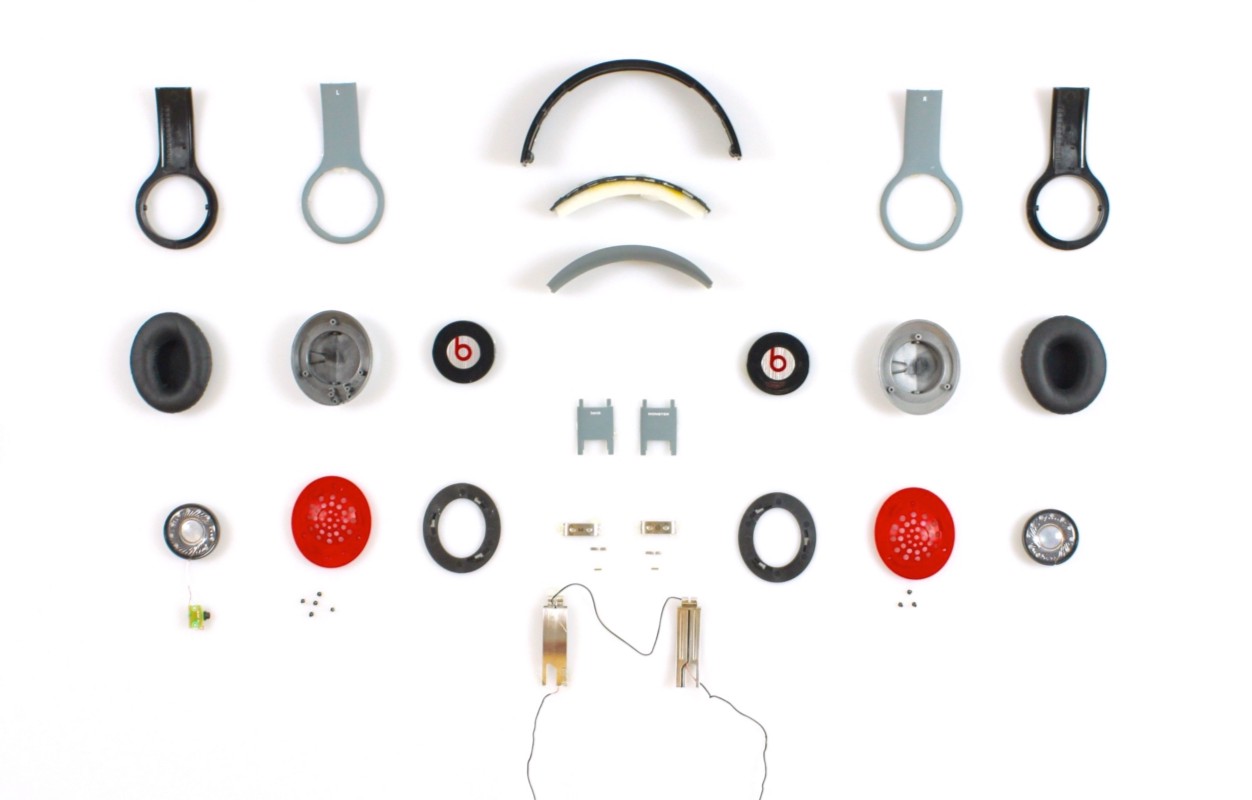

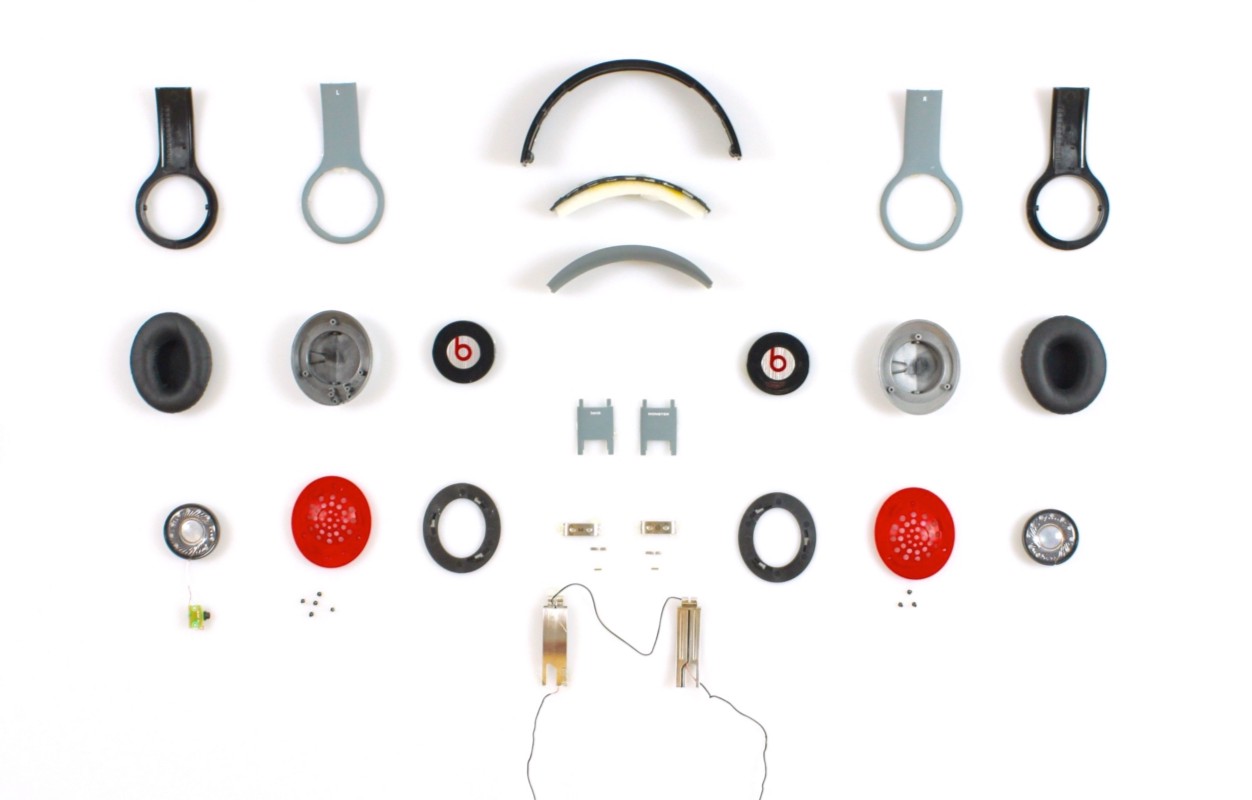

Lots of optimizations are to be expected in a product manufactured in the millions of units: snaps and glue are used for assembly rather than screws (which require lots of human manipulation) and almost every part is injection molded plastic (which is essentially free at high volumes).

Anytime I take a product apart there are a few exciting surprises to solve some tricky problems. Here’s what I found for Beats:

Use of metal components to increase weight

Luckily the Beats headphones are fairly easy to disassemble, despite a few pesky glue joints.

One of the great things about the solo headphones is how substantial they feel. A little bit of weight makes the product feel solid, durable, and valuable. One way to do this cheaply is to make some components out of metal in order to add weight. In these headphones, 30 percent of the weight comes from four tiny metal parts that are there for the sole purpose of adding weight.

The two larger parts are cast zinc. Cast parts are similar to injection molded parts in that there is a tooling cost and a per-part cost. Compared to injection molding, the tool is marginally more expensive, but the per-part costs are higher, and the tools do not last as long.

The brilliant thing here is that the two large metal parts are not mirror images of each other — they are actually the same part! This means that only one tool would need to be made to produce both parts, which saves money in tool design and number of tools. It also makes the headphones easier to assemble, since there are fewer unique parts.

Complex mold design of headband

One-third of the entire weight of the headphones comes from metal weights.

This is a somewhat common trick to make products feel more substantive.

This part probably has the highest tooling cost of any of the parts in the headphones, because it requires many cams in order for the part to be released from the mold. Cams allow for parts of the mold to move perpendicular to the parting line. These extra parts have to meet perfectly, in order for the parts to be molded properly. It is easy to tell what direction the two halves of the mold pulled apart from the round dots you can see in the photo above — those are ejector pin marks, from where the part was pushed out of the tool.

From the flashing along the long snaps at the top of the part, I can tell there are two side actions that were used to create the undercut. You can see parting lines in the part right under the snaps, and at the bottom of the circle.

Close-up of witness lines on inner ear cup frame. Many actions and slides are necessary to create this complex part.

You can also tell that inside the circle where the ear cup goes, there were actions to create the pins that the ear cup swivels on — the witness lines are visible, even though it has been post-polished.

Minimal use of screws

Both parts of the ear cups are made from two totally different molds so a to avoid the extra screw holes on the right cup.

Screws are cheap but are tedious to install, hence nearly every part on this product is snapped or glued together. You can see how the number of screws are optimized at the cost of cutting two more molds by comparing the left and right speaker grills and speaker cups — one of them has an extra two screw holes. Screws are great here because they make sure the PCB does not rattle around near your ear — however, they could have shaved off some assembly time by using heat stake bosses, or simply trapping the PCB between the red plastic and the ear cup.

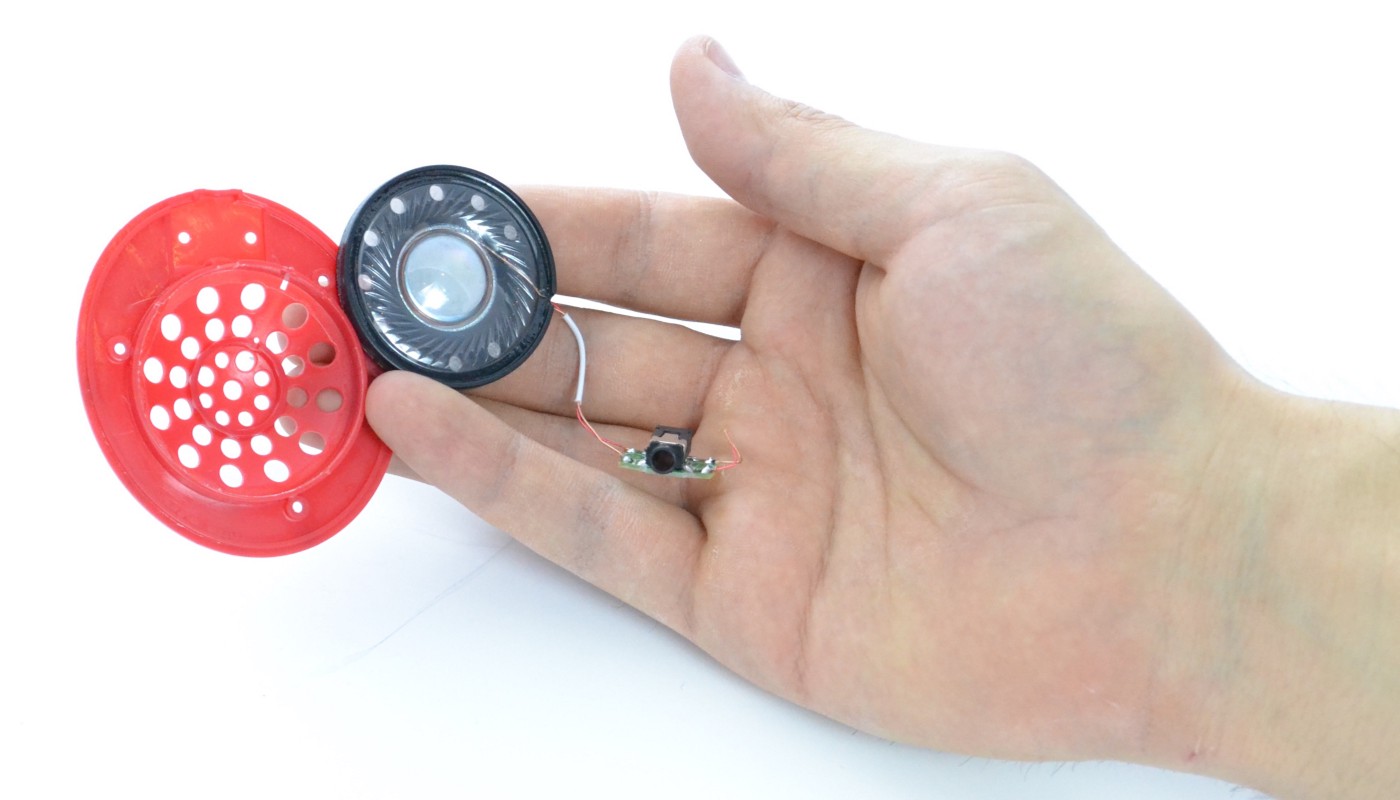

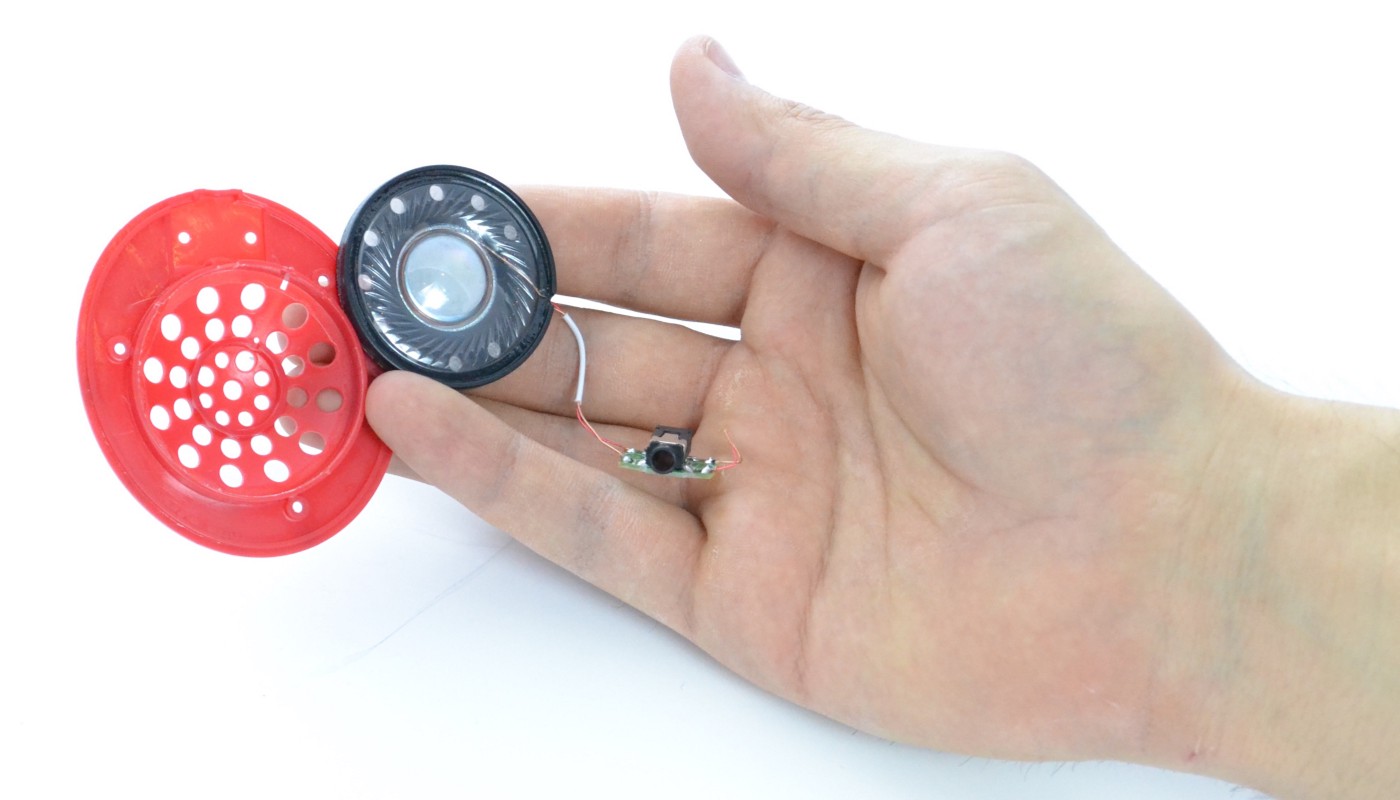

Complete commodity earphone drivers

So, do Beats by Dre headphones really enhance the bass? I couldn’t tell from the product teardown but the generic drivers make it seem unlikely. I was impressed, however, by the look and feel that was achieved with so few parts.

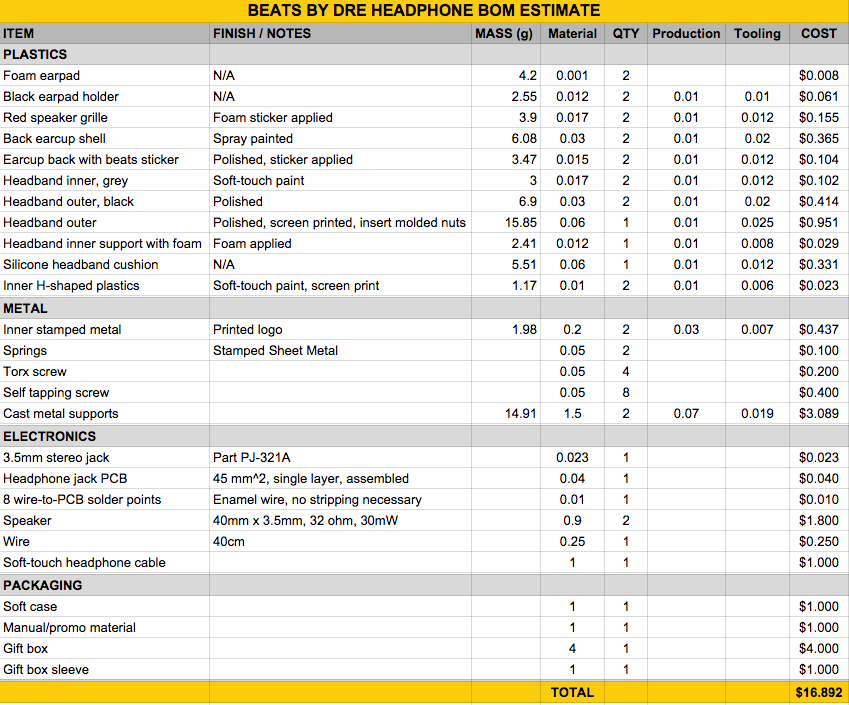

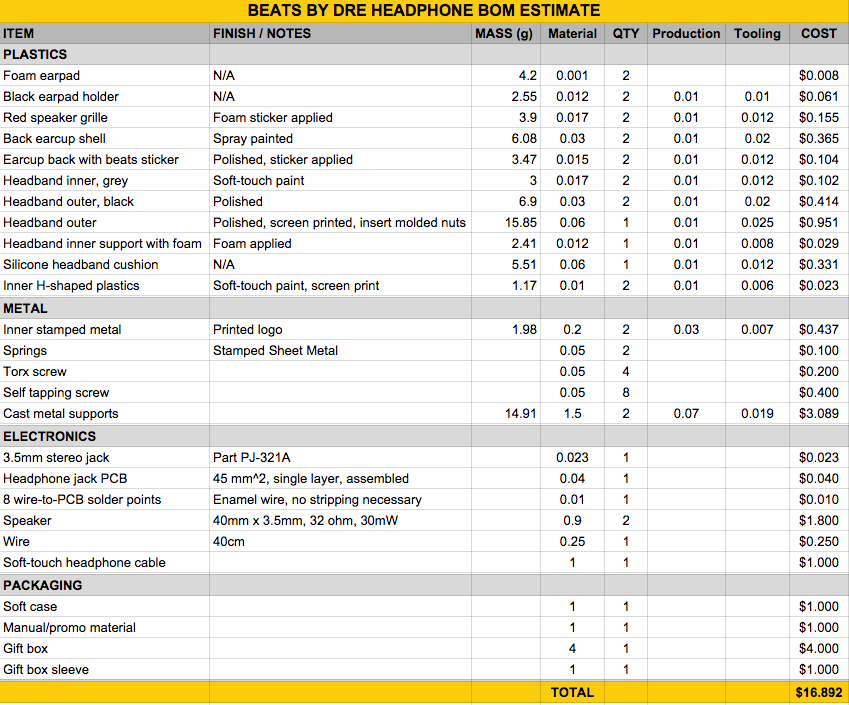

While it’s difficult to accurately reverse engineer the COGS of a product, I will do my best with each product that I tear down. In this BOM, I break it down into several categories — plastics, metal parts and electronic parts.

*Part prices for plastics, metal, and electronics takes various assumptions into account.

****

I estimate that the COGS without labor or shipping is $16.89 — yet Beats is able to successfully retail these headphones for $199+. This is the power of brand. Dr. Dre and Jimmy Iovine have leveraged their personal backgrounds and a sleek design to launch a remarkable brand that’s become fundamental to music pop culture.

*Plastic part price takes the following assumptions into account:

*Metal part price takes the following assumptions into account:

*Electronics part price takes the following assumptions into account:

A version of this post originally appeared on Medium.

Follow Ben Einstein on Twitter: www.twitter.com/BenEinstein

This post was co-authored with Avery Louie.

It’s nearly impossible to be on a train, fly on a plane or walk down the street without spotting the iconic “b” logo. Beats has been extremely successful in marketing its headphones and now enjoys large market appeal. But with a sky-high retail price of $199, is there more to Beats than meets the eye?

Lots of optimizations are to be expected in a product manufactured in the millions of units: snaps and glue are used for assembly rather than screws (which require lots of human manipulation) and almost every part is injection molded plastic (which is essentially free at high volumes).

Anytime I take a product apart there are a few exciting surprises to solve some tricky problems. Here’s what I found for Beats:

Use of metal components to increase weight

Luckily the Beats headphones are fairly easy to disassemble, despite a few pesky glue joints.

One of the great things about the solo headphones is how substantial they feel. A little bit of weight makes the product feel solid, durable, and valuable. One way to do this cheaply is to make some components out of metal in order to add weight. In these headphones, 30 percent of the weight comes from four tiny metal parts that are there for the sole purpose of adding weight.

The two larger parts are cast zinc. Cast parts are similar to injection molded parts in that there is a tooling cost and a per-part cost. Compared to injection molding, the tool is marginally more expensive, but the per-part costs are higher, and the tools do not last as long.

The brilliant thing here is that the two large metal parts are not mirror images of each other — they are actually the same part! This means that only one tool would need to be made to produce both parts, which saves money in tool design and number of tools. It also makes the headphones easier to assemble, since there are fewer unique parts.

Complex mold design of headband

One-third of the entire weight of the headphones comes from metal weights.

This is a somewhat common trick to make products feel more substantive.

This part probably has the highest tooling cost of any of the parts in the headphones, because it requires many cams in order for the part to be released from the mold. Cams allow for parts of the mold to move perpendicular to the parting line. These extra parts have to meet perfectly, in order for the parts to be molded properly. It is easy to tell what direction the two halves of the mold pulled apart from the round dots you can see in the photo above — those are ejector pin marks, from where the part was pushed out of the tool.

From the flashing along the long snaps at the top of the part, I can tell there are two side actions that were used to create the undercut. You can see parting lines in the part right under the snaps, and at the bottom of the circle.

Close-up of witness lines on inner ear cup frame. Many actions and slides are necessary to create this complex part.

You can also tell that inside the circle where the ear cup goes, there were actions to create the pins that the ear cup swivels on — the witness lines are visible, even though it has been post-polished.

Minimal use of screws

Both parts of the ear cups are made from two totally different molds so a to avoid the extra screw holes on the right cup.

Screws are cheap but are tedious to install, hence nearly every part on this product is snapped or glued together. You can see how the number of screws are optimized at the cost of cutting two more molds by comparing the left and right speaker grills and speaker cups — one of them has an extra two screw holes. Screws are great here because they make sure the PCB does not rattle around near your ear — however, they could have shaved off some assembly time by using heat stake bosses, or simply trapping the PCB between the red plastic and the ear cup.

Complete commodity earphone drivers

So, do Beats by Dre headphones really enhance the bass? I couldn’t tell from the product teardown but the generic drivers make it seem unlikely. I was impressed, however, by the look and feel that was achieved with so few parts.

While it’s difficult to accurately reverse engineer the COGS of a product, I will do my best with each product that I tear down. In this BOM, I break it down into several categories — plastics, metal parts and electronic parts.

*Part prices for plastics, metal, and electronics takes various assumptions into account.

****

I estimate that the COGS without labor or shipping is $16.89 — yet Beats is able to successfully retail these headphones for $199+. This is the power of brand. Dr. Dre and Jimmy Iovine have leveraged their personal backgrounds and a sleek design to launch a remarkable brand that’s become fundamental to music pop culture.

*Plastic part price takes the following assumptions into account:

- 2 percent scrap rate

- 1 cavity / tool

- 20 percent regrind allowed

- No additives (Meaning not glass filled, etc)

- Machine rate, setup labor, and direct labor adjusted per component

- Cycle time of 15 seconds is assumed per part

- Markup is not included

- Tooling cost is amortized assuming 1M units

- No downtime factored into molding machine

- Assume simple tooling (It’s known that some of these parts have actions, but was not added to the tooling cost)

- Tooling cost assumptions are broad and based in China

- Production costs based on Asia. Somewhat conservative and broad

*Metal part price takes the following assumptions into account:

- 5 percent scrap rate

- 160 ton press

- 95 percent uptime, 8hr setup

*Electronics part price takes the following assumptions into account:

- Quoted from Zirui @ qty 6000 FOB

- CB with routing and v-score, 1 part placement

- 25 seconds to solder @ Shenzhen min wage RMB2,030/mo = US1.50/hr

- Exact equivalent not found; found 40mm x 5.6mm, 32 ohm, 25mW for0.75

A version of this post originally appeared on Medium.

Follow Ben Einstein on Twitter: www.twitter.com/BenEinstein