stoN_Cold

Super Member

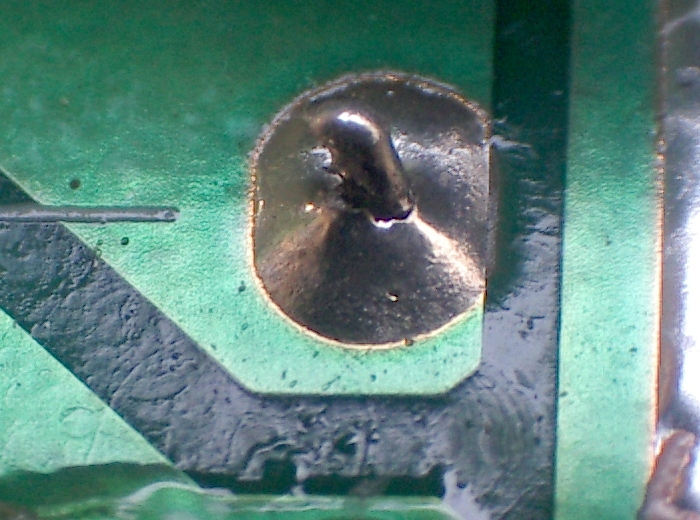

Can anyone recommend any 22.5mm 4-pin power caps in existence that would just drop in?

http://www.ebay.com/itm/Electrolyti...hash=item3f76c72d16:m:mvY9LpMg-RlKMgDKZdq2T6Q

http://www.ebay.com/itm/4pcs-RUBYCO...a18d5bc&pid=100005&rk=2&rkt=6&sd=272575704342

http://www.ebay.com/itm/F-T-Al-ELKO...260390?hash=item3f755230e6:g:n0wAAOxyn9BRZy-C