This is becoming a P.I.T.A. :thumbsdn:

Mechanically I've got this 1229Q working pretty well. The motor is a touch noisy and could use a disassembly and lube but that's for another day. The usual old lube issues around the idler arm and speed control switch and missing steuerpimpel have all been addressed. The auto functions work well as well as the Single/Multi function.

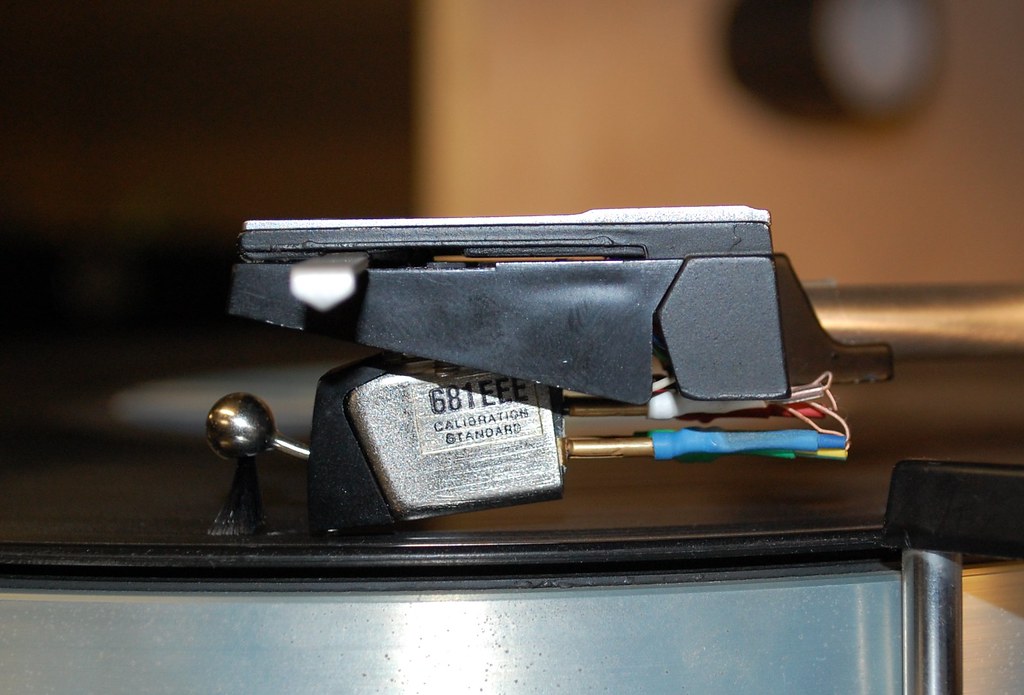

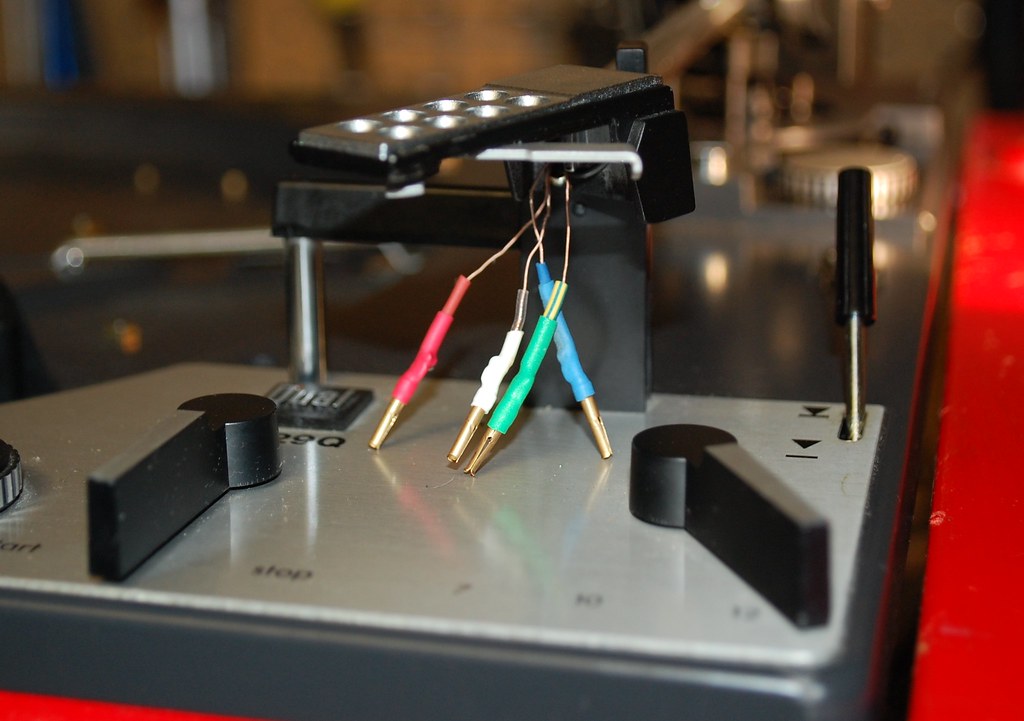

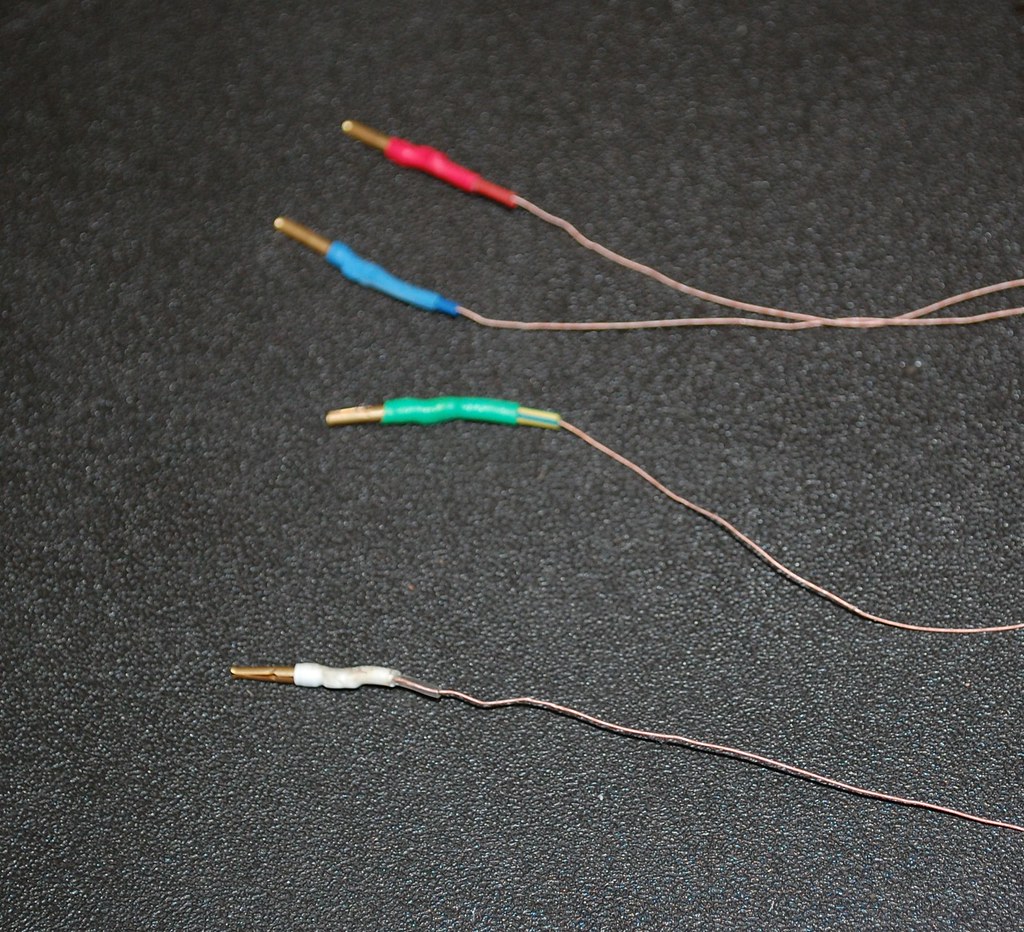

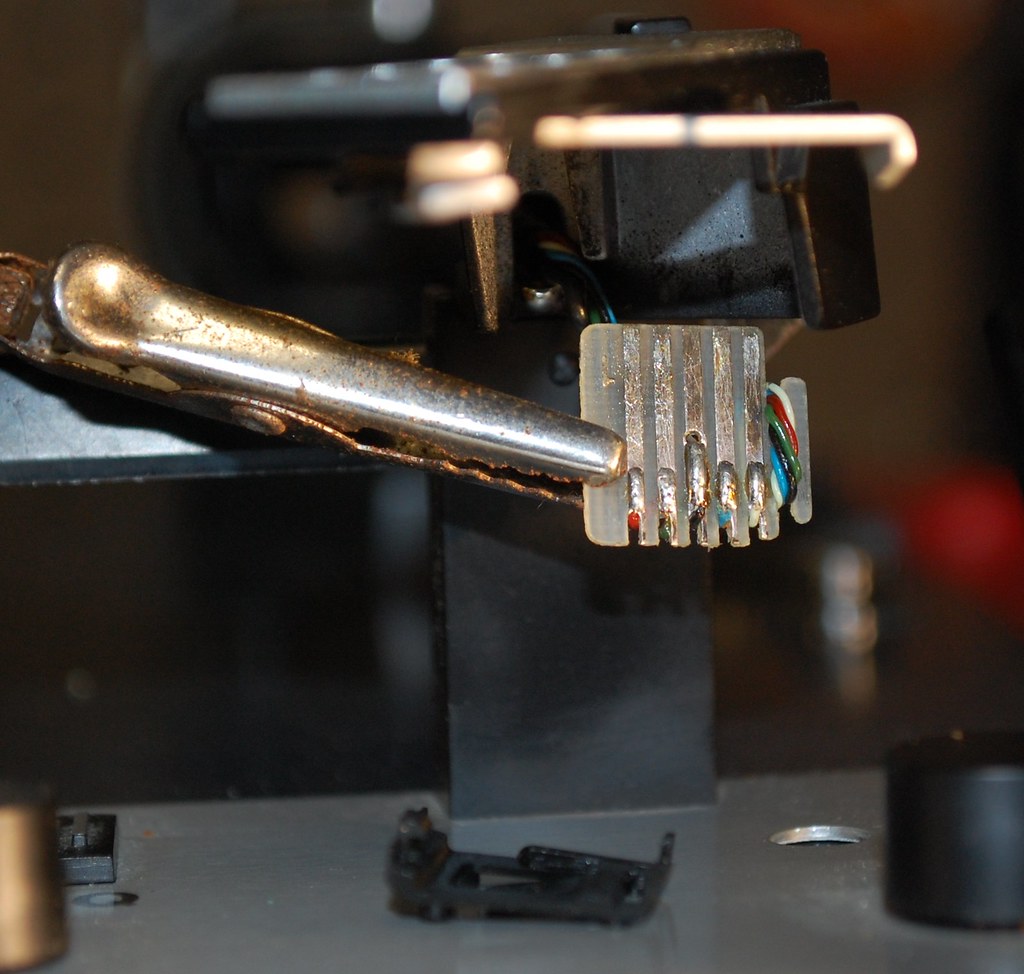

However, I still get just one channel consistently. The Stanton 681EEE on it is good, reading about 1500 ohms on each side. There is continuity from the cartridge to the ends of the sled contacts (the style with the folded over types, not the spring loaded pins). I've cleaned the tarnish off the contacts with a salt water & aluminum foil bath, and pencil eraser on the tonearm end of things. I manipulated the sled contacts in various ways to see if I could make them make better contact. I've used a different sled (with the springy pins) and cartridge.

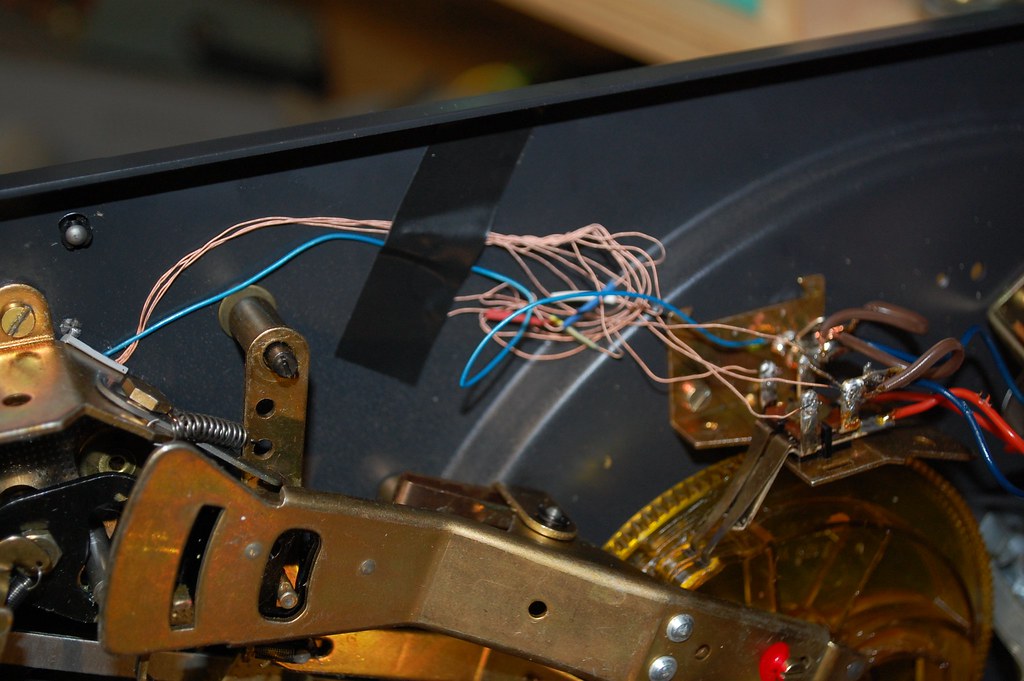

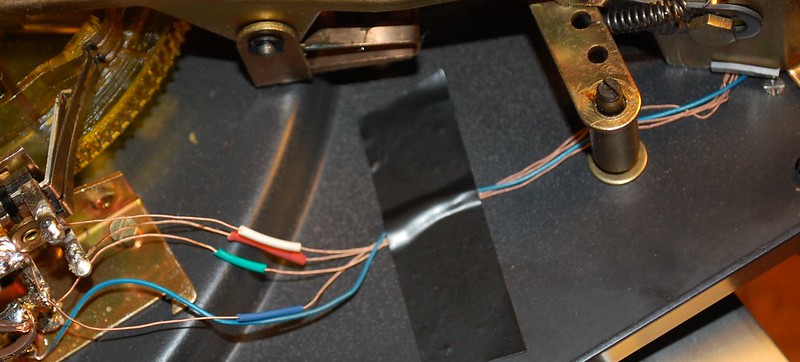

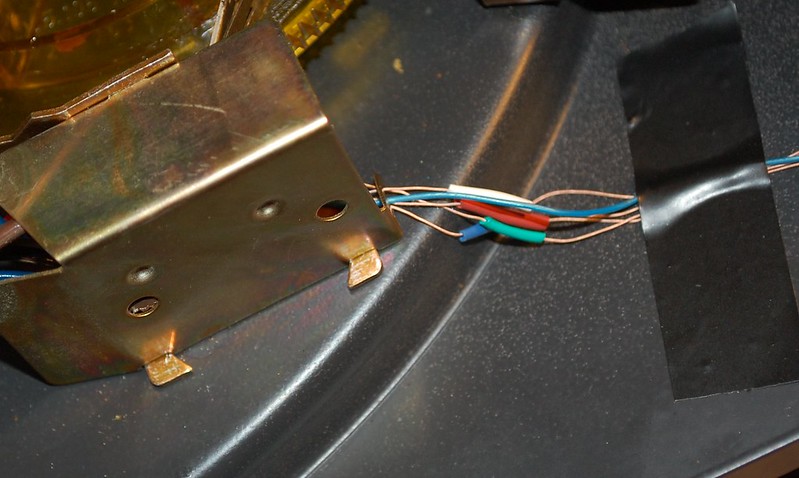

There is continuity from the tonearm contacts back to the mute switch block on all 4 leads. I've cleaned the mute switch contacts and made sure they are only closed (tested with meter) when the arm is moving as they should be. I cleaned the RCA jacks with Deoxit on a Q-Tip. I used 3 different RCA cables. I reflowed the solder joints at the mute switch and the RCA board. I cut the wire ground bridge between the 2 channels at the mute switch, and later re-soldered it.

Now if you are still with me, here it gets somewhat interesting. I initially had it plugged into my NAD phono pre-amp. A few times when I pulled and re-inserted the RCA cord at the pre-amp end the other channel came through. It usually only worked for a few seconds to a few minutes and then it would go dead again. The end of the RCA at the turntable was not touched or affected by pulling on the pre-amp end. Ok, maybe the pre-amp is the problem. Switching sides though did not indicate the pre was the issue. Then I bypassed the NAD altogether and went straight to the Yamaha receiver Phono in. Same issue; one channel stays dead.

The "bad" channel (red/green) does produce a pop when the mute switch engages and disengages during the tonearm cycle. Also, when I touch the cartridge leads on that side I get a significant hum. On the "good" white/blue side I don't get the muting switch pop and I get no noise when I touch it.

It might be some kind of ground loop, or maybe a bad tonearm wire but it's frustrating whatever it is.

Mechanically I've got this 1229Q working pretty well. The motor is a touch noisy and could use a disassembly and lube but that's for another day. The usual old lube issues around the idler arm and speed control switch and missing steuerpimpel have all been addressed. The auto functions work well as well as the Single/Multi function.

However, I still get just one channel consistently. The Stanton 681EEE on it is good, reading about 1500 ohms on each side. There is continuity from the cartridge to the ends of the sled contacts (the style with the folded over types, not the spring loaded pins). I've cleaned the tarnish off the contacts with a salt water & aluminum foil bath, and pencil eraser on the tonearm end of things. I manipulated the sled contacts in various ways to see if I could make them make better contact. I've used a different sled (with the springy pins) and cartridge.

There is continuity from the tonearm contacts back to the mute switch block on all 4 leads. I've cleaned the mute switch contacts and made sure they are only closed (tested with meter) when the arm is moving as they should be. I cleaned the RCA jacks with Deoxit on a Q-Tip. I used 3 different RCA cables. I reflowed the solder joints at the mute switch and the RCA board. I cut the wire ground bridge between the 2 channels at the mute switch, and later re-soldered it.

Now if you are still with me, here it gets somewhat interesting. I initially had it plugged into my NAD phono pre-amp. A few times when I pulled and re-inserted the RCA cord at the pre-amp end the other channel came through. It usually only worked for a few seconds to a few minutes and then it would go dead again. The end of the RCA at the turntable was not touched or affected by pulling on the pre-amp end. Ok, maybe the pre-amp is the problem. Switching sides though did not indicate the pre was the issue. Then I bypassed the NAD altogether and went straight to the Yamaha receiver Phono in. Same issue; one channel stays dead.

The "bad" channel (red/green) does produce a pop when the mute switch engages and disengages during the tonearm cycle. Also, when I touch the cartridge leads on that side I get a significant hum. On the "good" white/blue side I don't get the muting switch pop and I get no noise when I touch it.

It might be some kind of ground loop, or maybe a bad tonearm wire but it's frustrating whatever it is.

Last edited: