Before you mount the assembly plate back on, clean the old grease off each fly-wheel center shaft, and put a small amount of Lube-Gel on the steel-ball.

Attach the plastic connector back on the capstan-motor and slide the whole assemby-plate back in the same way it came out. Be careful so now wires are between and in the fly-wheels.

You need a long screw-driver or hook to lift up the drive-belt on to the pulley at the same time you guiding the plate back.

Also be sure the Timer function plate goes in the slot on top of the assembly plate.

This can be little tricky but have patience:

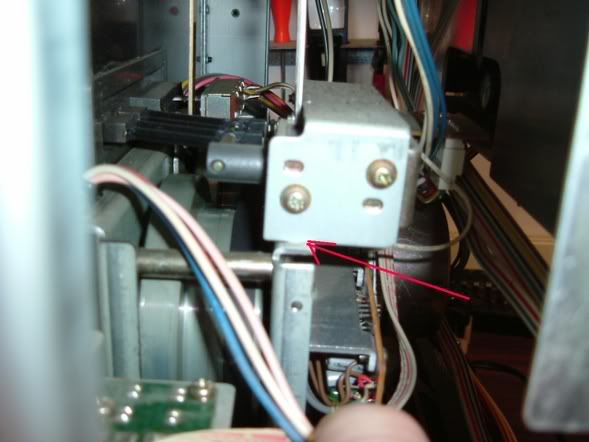

See here:

Attach the lower center screw on the plate first, but don't tighten it until all the other 5 is attached.

When it's all back in place, spin one fly-wheel both directions with your finger so the belt guide itself, and you can check how the belt changes position on both fly-wheels.

Attach new tie-straps on the right side + check so no wires are close to the fly-wheels.

Check the timer buttons on the front so they function properly.

Mount the pinch-rollers back on and put one small drop of gun-oil on each shaft, be sure you have those small black washers on each side of the pinch-roller.

Washer:

Covers back on the pinch-rollers, and check the movement up and down, should be smooth on both L + R. :yes:

Time to test with tape and power on:

Press Play in both directions and check the belt from the back and see how it behave.

Try this several times before you assembly the plastic cabinet and wood-cabinet.

Good Luck Eric. :thmbsp:

I hope it goes well with the surgery.