kevinmasters

Well-Known Member

Okay folks, it looks amazing, we all agree! NOW, isn't there someone here who has a good guess as to what may be going on with the electrical issue?:scratch2:

Very nice indeed. I have one that I've been meaning to restore for sometime, my major hangup... I only have one of the feet. Does anyone know of a source for the feet on these units? Also, are they like some other TT's where the feet's springs are unique in spring rate and thereby needing to be installed in the proper positions? How would I find out which one's go where if that is indeed the case? Sorry for the thread-jacking

Keyrimany that turned out nice. Well done.

I have a 518 that I've been thinking about sprucing up. I thought I was pretty original as I was going to paint it copper, but I guess I'm not the first person with that idea. Still, I'll probably do that though.

Did you find it easy to take apart? Mine works perfectly now and I'm a little nervous about disassembling a perfectly good TT to make it purdy.

My first soldering job was reattaching the lead wire on a Boston driver's voice coil. Total hack job but I only dimpled the cone instead of melting clean clean through it, so I'm considering that a success.

Hey guys thanks again......But I am still having problems with the right channel, along with the humming sound as i get close to the head shell.

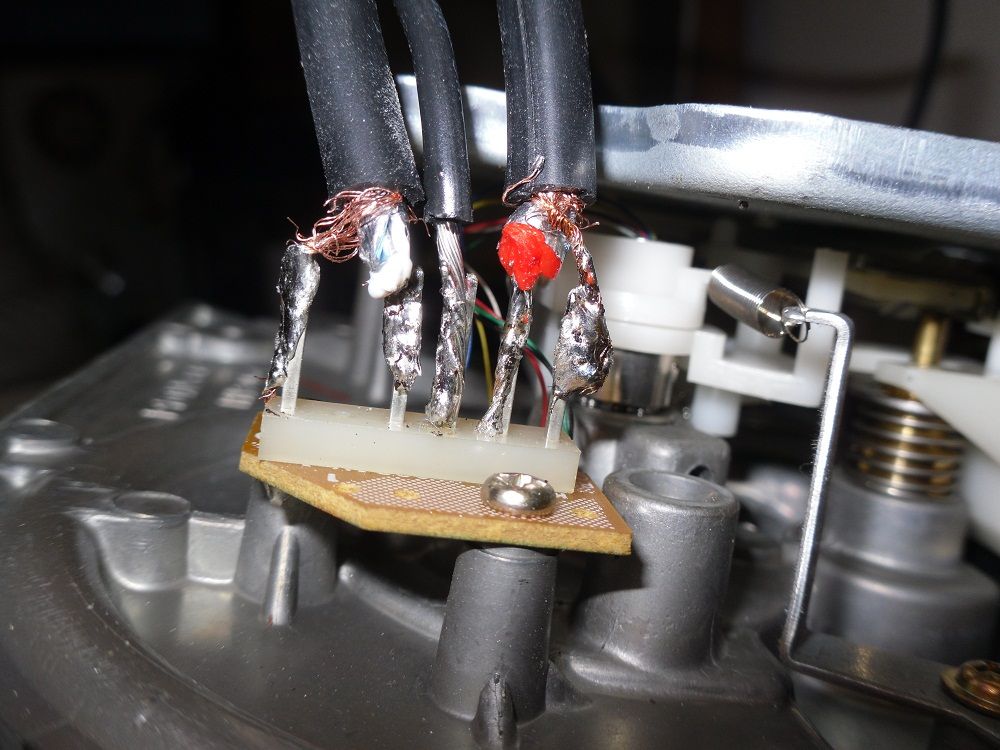

Have you checked the underside of that small circuit board? Maybe the soldering of the tonearm wires were compromised? Even if it looks OK, you may want to heat those spots up with an iron. Also, you'be for some stray wires that you may want to clean up, just in case. They look like they could touch of manipulated enough.

I haven't had the time to look in to which one was the problem. I will keep you all posted.

I haven't had the time to look in to which one was the problem. I will keep you all posted.

But on the other hand I do get to spend time at the park and the apple orchard:yes::yes: Got to love my girls

But on the other hand I do get to spend time at the park and the apple orchard:yes::yes: Got to love my girls [/URL]

[/URL]Having recently been through this...I am not new to TT's but was sort of new to continuity testing ...Do you have a meter ? If not spend the dang 15 bucks and get one...Mine has an Ohms setting that beeps for continuity testing...doesn;t get any easier than that...

Now, your solder job (sorry, I mean this kindly) sucks. WAY too much..think of a small dot you see on other solder spots...like a spit ball..yours looks like vesuvius erupted...

Okay...so with your new meter you are going to check continuity from point to point..each leg.

So ..from the headshell - R+ to the tonearm wire in the body (red) one probe on each...Beep. Good. R- (green) to the tonearm wire in the body. Beep. Good. same for left side (L+ white, L-blue) ..beep beep ..good.

Now..do the same out to your RCA's from inside the body where you just checked is good out to the RCA plugs. Right tip is R+. Right outter is R-.

You'll find your break and fix...

If you need more or pics, let us know..

Now...why do I say this is new to me ? Because while I have worked on tables, I never did continuity testing until this weekend...it helped me solve a dual turntable channel loss and hum issue. Now its perfect and I have a new trick in my magic bag

Hope this helps...