roger2

.

One of my current projects. Before winter I want to fill the voids in these steps to seal out moisture and thus prevent continuing damage.

My thinking is to use mortar and (where necessary) use broken chunks of brick to fill the voids and make a new surface flush with the old surface. Then, either sooner or later (depending on curing time) the entire step unit would receive a surface coating/sealant of either paint or perhaps something better that someone might suggest.

Questions floating around in my mind presently:

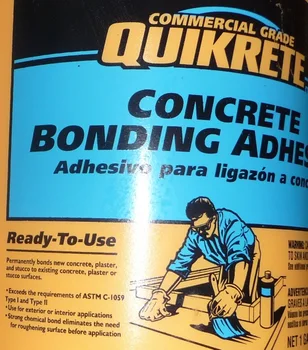

1) What would be the best thing to use to bond to the old surfaces? Of course I will clean away dust and loose bits. I have some Type N mortar from a previous brick laying project. Would Type N work well? Is there something more specific to this type of application that might be better than Type N mortar?

2) How much curing time wold be needed before applying a sealing surface coating?

3) What would be the best type of surface coating? Exterior floor paint? Is there something else?

Thanks in advance...

My thinking is to use mortar and (where necessary) use broken chunks of brick to fill the voids and make a new surface flush with the old surface. Then, either sooner or later (depending on curing time) the entire step unit would receive a surface coating/sealant of either paint or perhaps something better that someone might suggest.

Questions floating around in my mind presently:

1) What would be the best thing to use to bond to the old surfaces? Of course I will clean away dust and loose bits. I have some Type N mortar from a previous brick laying project. Would Type N work well? Is there something more specific to this type of application that might be better than Type N mortar?

2) How much curing time wold be needed before applying a sealing surface coating?

3) What would be the best type of surface coating? Exterior floor paint? Is there something else?

Thanks in advance...

Last edited: