Juan9568

Member

Hi guys. I'm about to begin with the restoration of my uncle's old Sansui 9090DB. The receiver is in a pretty bad condition, it has been serviced by bad technicians and they replaced parts with cheaper or wrong ones.

Issues:

. Burnt resistors

. Blown fuses

. Blown outputs

. Scratchy pots

A few months ago I decided to start with the restoration myself as there are no good technicians where I live and trying to get quality parts it's almost impossible.

I decided to do the following:

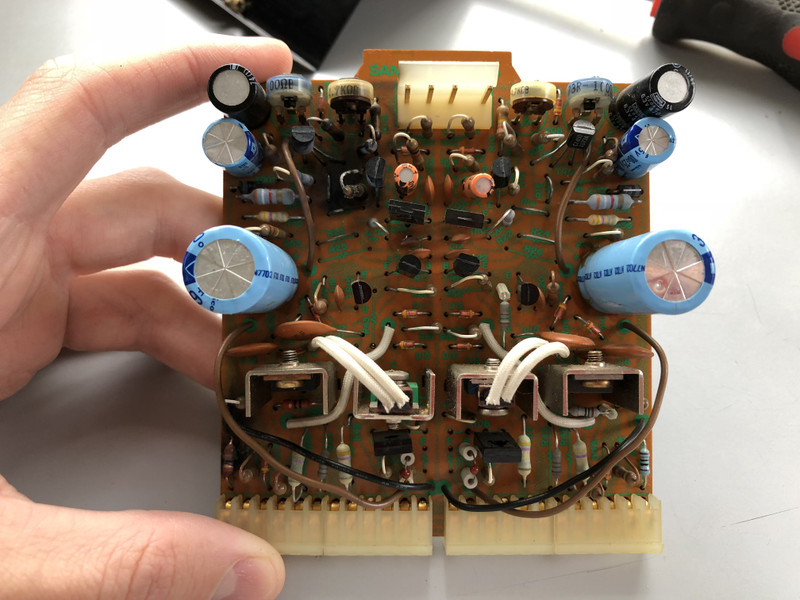

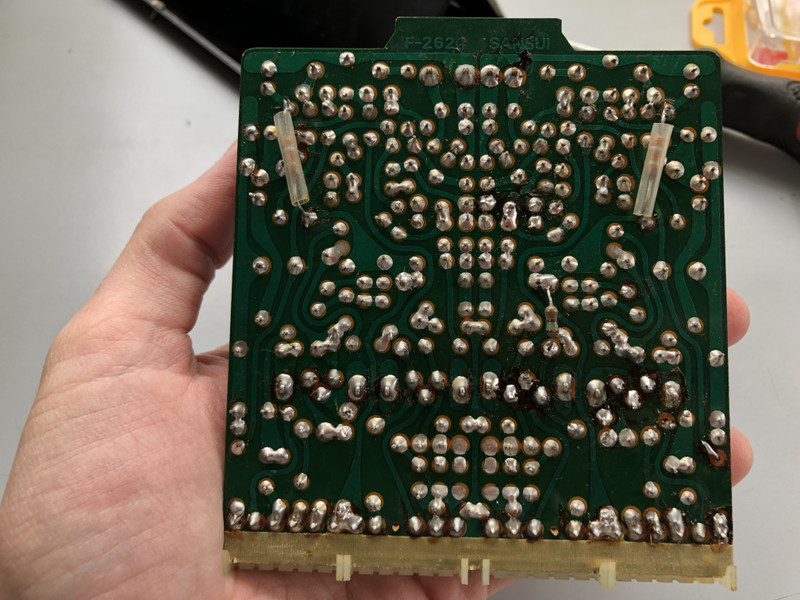

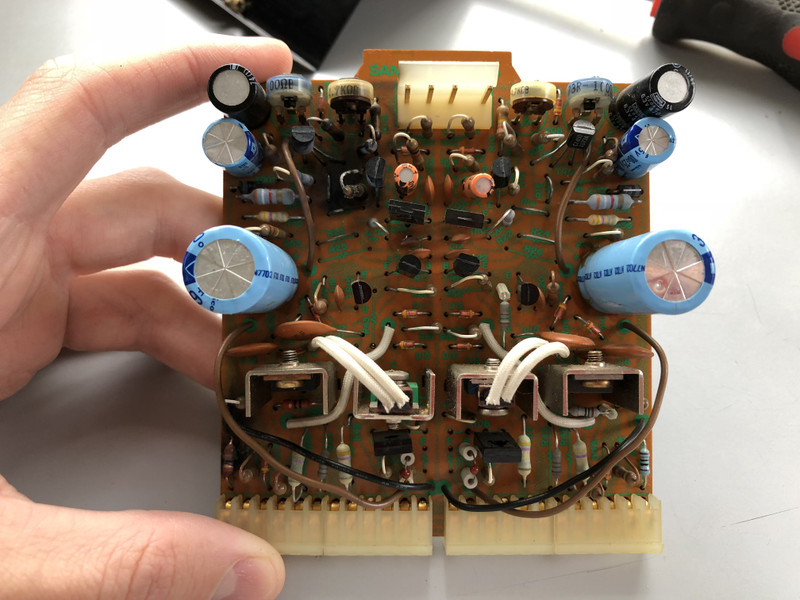

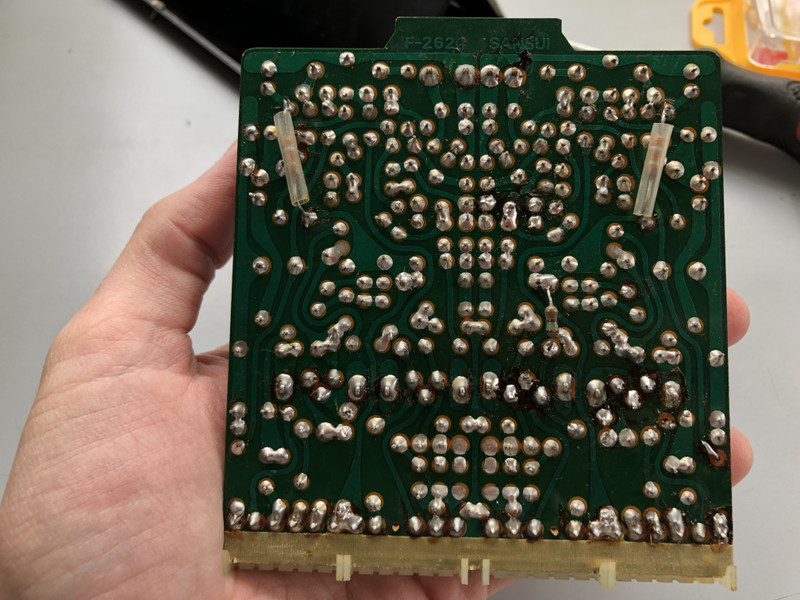

. Rebuild from scratch F2624 Driver board

. Replace capacitors and resistors from F2656 Power supply

. New fuses

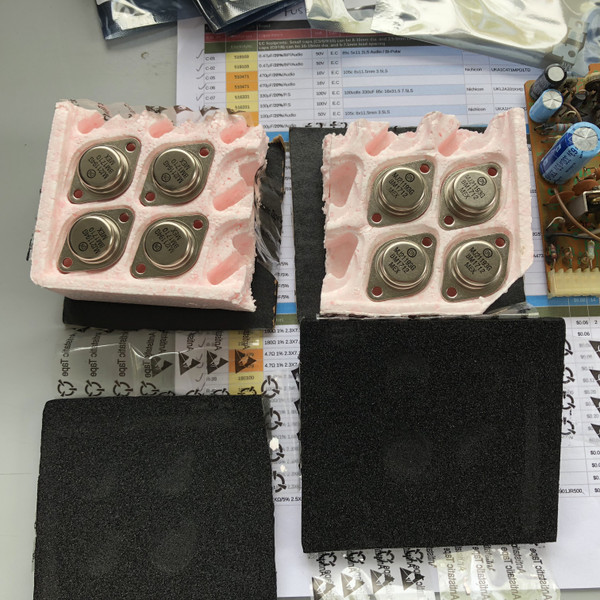

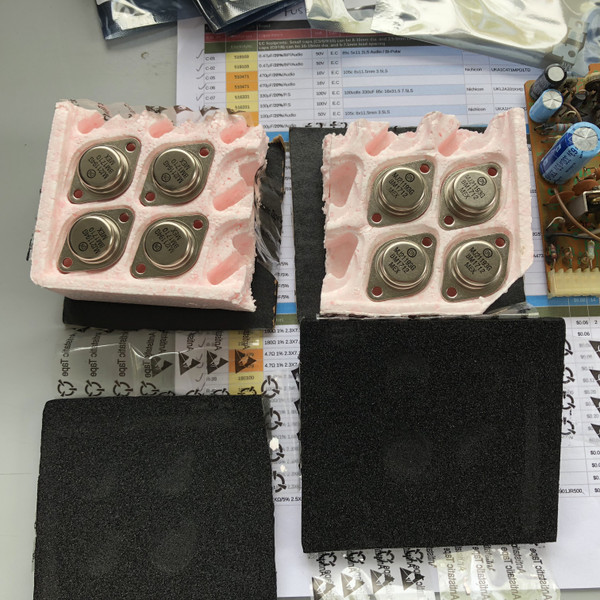

. New outputs

. Clean all pots

Because I'm not an expert in electronics I thought it would be easier for me to start with a new F2624 instead of troubleshooting the whole board. So I got the new F2624 PCB and most of the other parts from mouser and digikey.

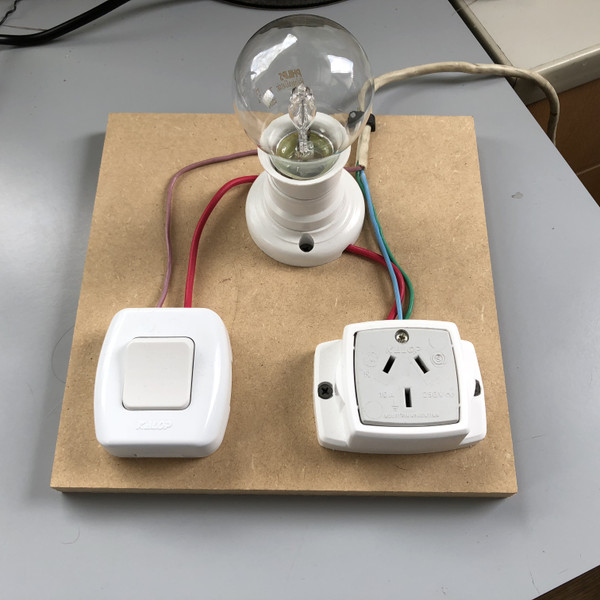

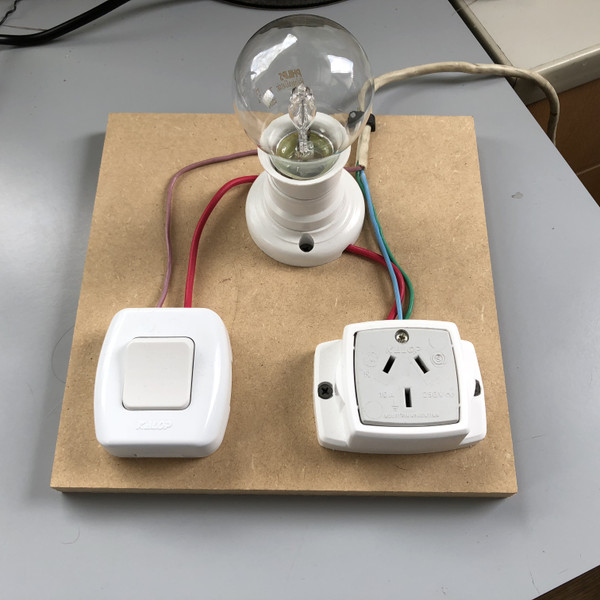

Also built myself a DBT cause I don't wanna blow everything up on the first run but I don't know yet what type of bulb I need to use for the thing to protect the amp, I got a 70W but don't know if it is the right wattage. I'm on a 220v area. Any suggestions??

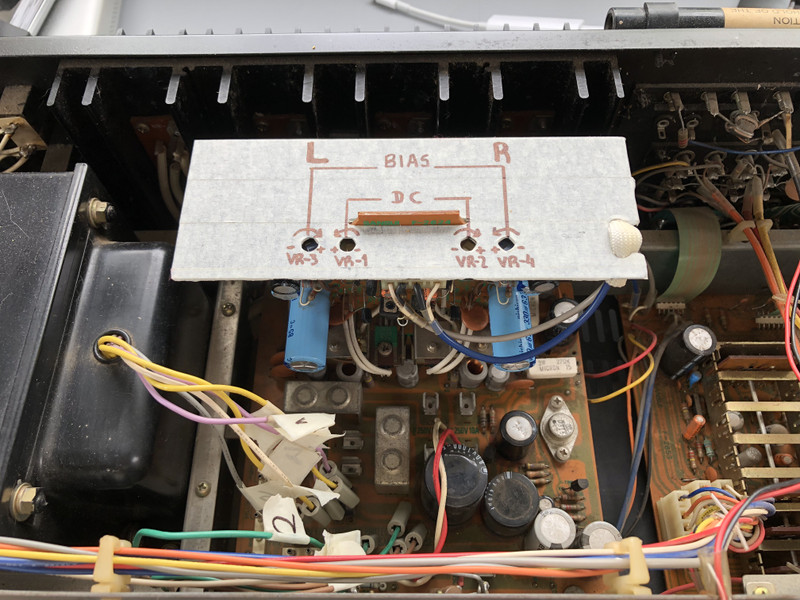

What most scares me is when time comes to adjust the DC and Bias current, I know it is a very fragile thing and needs to be done correctly.

I would really appreciate it if someone can give me any tips, tricks, suggestions so I can make this restoration right.

THanks!!!

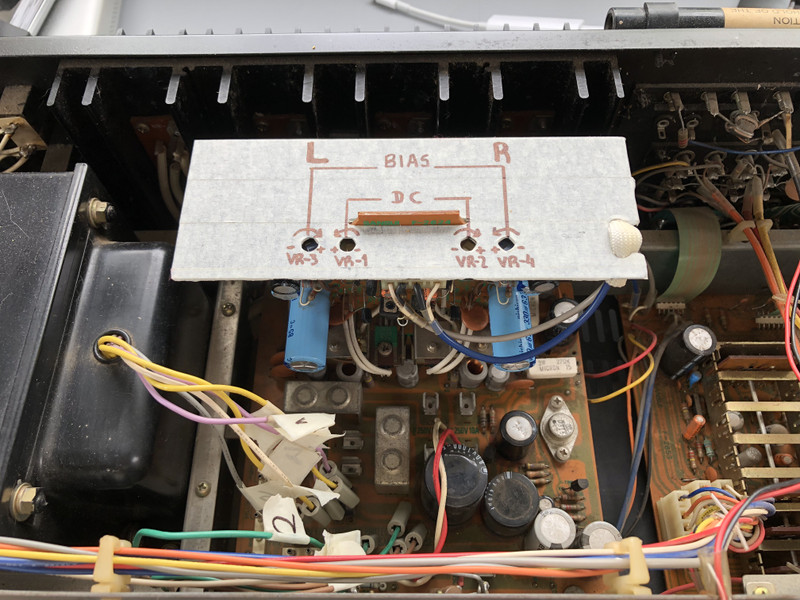

Here are some pics of the amp before I begin. I will be posting updates on my progress.

Issues:

. Burnt resistors

. Blown fuses

. Blown outputs

. Scratchy pots

A few months ago I decided to start with the restoration myself as there are no good technicians where I live and trying to get quality parts it's almost impossible.

I decided to do the following:

. Rebuild from scratch F2624 Driver board

. Replace capacitors and resistors from F2656 Power supply

. New fuses

. New outputs

. Clean all pots

Because I'm not an expert in electronics I thought it would be easier for me to start with a new F2624 instead of troubleshooting the whole board. So I got the new F2624 PCB and most of the other parts from mouser and digikey.

Also built myself a DBT cause I don't wanna blow everything up on the first run but I don't know yet what type of bulb I need to use for the thing to protect the amp, I got a 70W but don't know if it is the right wattage. I'm on a 220v area. Any suggestions??

What most scares me is when time comes to adjust the DC and Bias current, I know it is a very fragile thing and needs to be done correctly.

I would really appreciate it if someone can give me any tips, tricks, suggestions so I can make this restoration right.

THanks!!!

Here are some pics of the amp before I begin. I will be posting updates on my progress.