To me the term 'recapping' means just that, replacing ONLY electrolytic capacitors in an amplifier or receiver (or other piece of equipment), which to me makes it a half-arsed job.

Rant

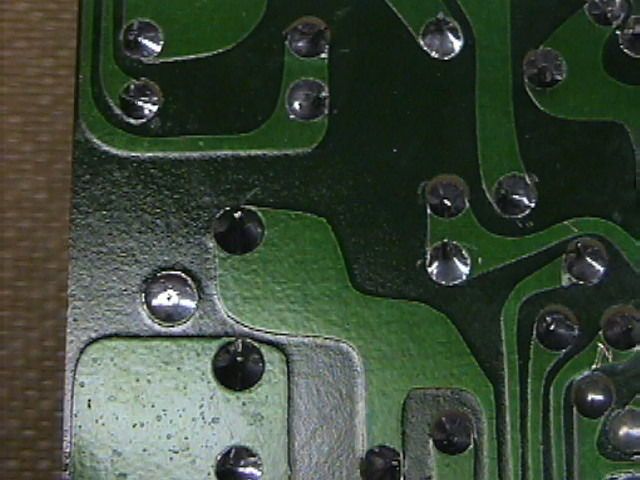

But if the unit is more than say 20 years old you really MUST REPLACE the bias and offset trimmers. All too often these are the 'open frame' type which have hopelessly oxidised and are too unreliable resistance wise to even consider leaving in place. Don't bother with deoxit, cramolin, or your particular poison for cleaning contacts on these things - CHANGE THE BLOODY THINGS for new !

There I said it...

Rant off.

Rant

But if the unit is more than say 20 years old you really MUST REPLACE the bias and offset trimmers. All too often these are the 'open frame' type which have hopelessly oxidised and are too unreliable resistance wise to even consider leaving in place. Don't bother with deoxit, cramolin, or your particular poison for cleaning contacts on these things - CHANGE THE BLOODY THINGS for new !

There I said it...

Rant off.

Last edited: