TankPopper

Well-Known Member

Hey guys.

Time for me to build another TT.. and fortunatly enough a L75 landed in my lap for dirty cheap - and in great condition!

My plan? go super HiTech! i want EVERYTHING to be cut by laser and make a Lego out of it. inspiration was naturaly drawn from the PTP. The body will be MDF (easy to cut by laser), the top plate and armboard will be 3mm stainless steel and the top will recieve a black surface using an acrylic board (laser cut as well..)

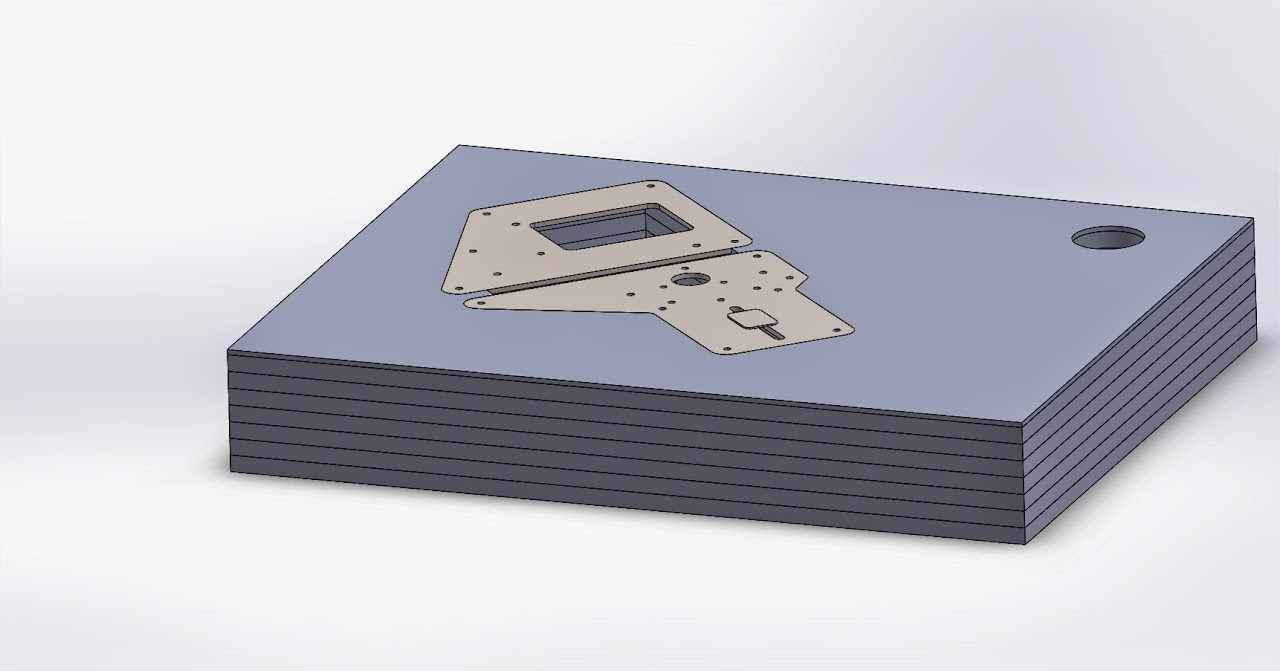

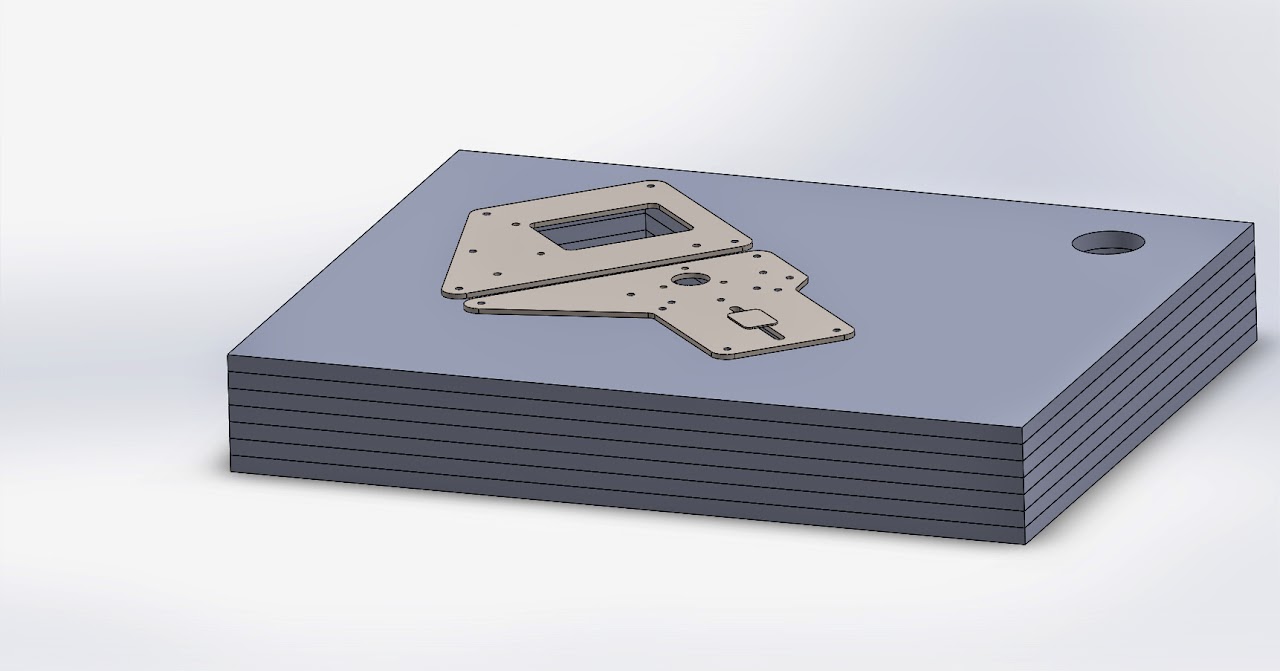

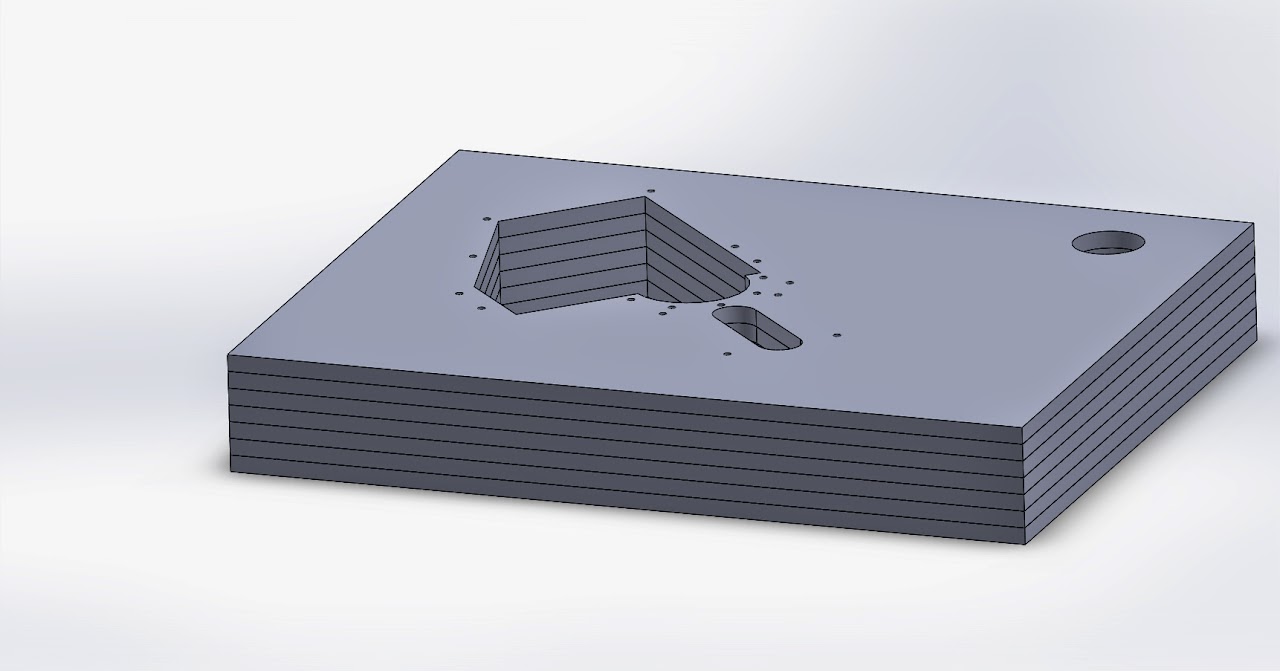

here are a few images of the work done so far:

top view

all the layers:

armboard and acrylic board removed:

top mdf board removed:

top plate imbedding board removed (3mm mdf...):

and just the base:

Alot more planning is still neccesary, mainly to make sure the LEGO aspect of it works fine.. i plan to make holes all over to help me brace the layers when glueing and maybe even cavities to fill sand \ led inside to plinth.

the only part not laser cut will be the side walls (not seen in the images). i plan to use a rather pail wood, probably oak.

any suggestions will be welcomed!

Tank out.

Time for me to build another TT.. and fortunatly enough a L75 landed in my lap for dirty cheap - and in great condition!

My plan? go super HiTech! i want EVERYTHING to be cut by laser and make a Lego out of it. inspiration was naturaly drawn from the PTP. The body will be MDF (easy to cut by laser), the top plate and armboard will be 3mm stainless steel and the top will recieve a black surface using an acrylic board (laser cut as well..)

here are a few images of the work done so far:

top view

all the layers:

armboard and acrylic board removed:

top mdf board removed:

top plate imbedding board removed (3mm mdf...):

and just the base:

Alot more planning is still neccesary, mainly to make sure the LEGO aspect of it works fine.. i plan to make holes all over to help me brace the layers when glueing and maybe even cavities to fill sand \ led inside to plinth.

the only part not laser cut will be the side walls (not seen in the images). i plan to use a rather pail wood, probably oak.

any suggestions will be welcomed!

Tank out.

:thmbsp:

:thmbsp: