I love my vintage systems but there is no denying that it's a PITA when the phone rings and I have to run over there and turn down the volume. A remote volume control, that's what I need!

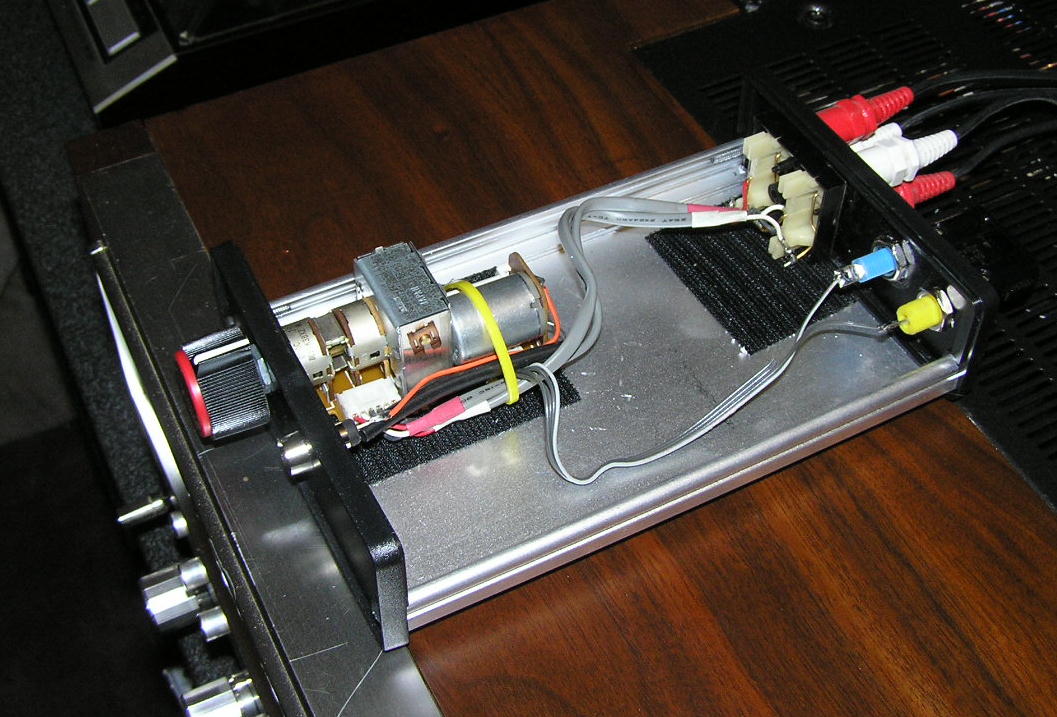

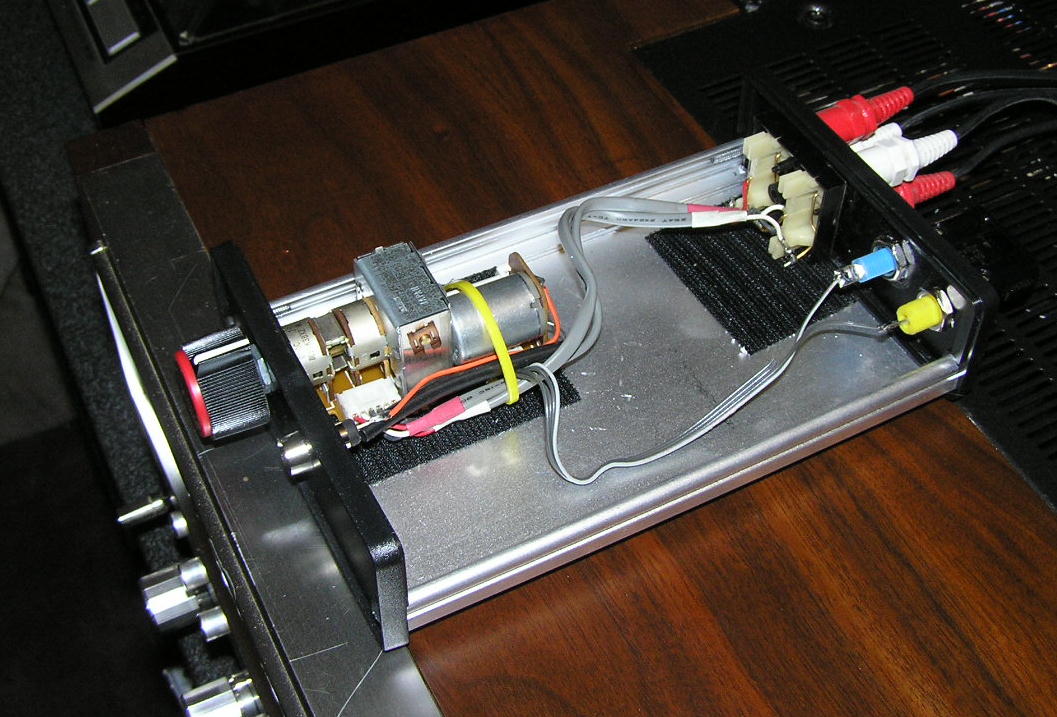

So here is this weekends project, a remote motorized volume control. Out of pocket costs - zero. All parts were lying around here and / or salvaged from junk units.

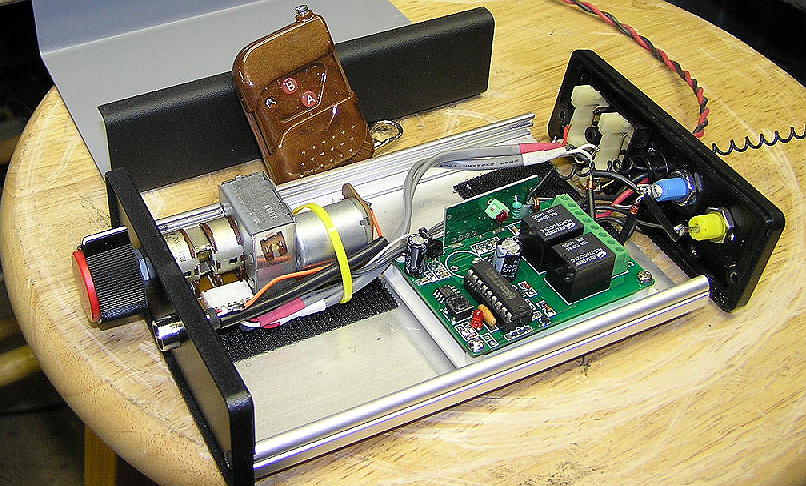

I removed the motorized volume control from a defunct Sony CD changer along with the 4 RCA connectors. Currently the remote is wired but I'm ordering a 2 channel RF remote from an ebay seller (~$18 shipped) to complete the project.

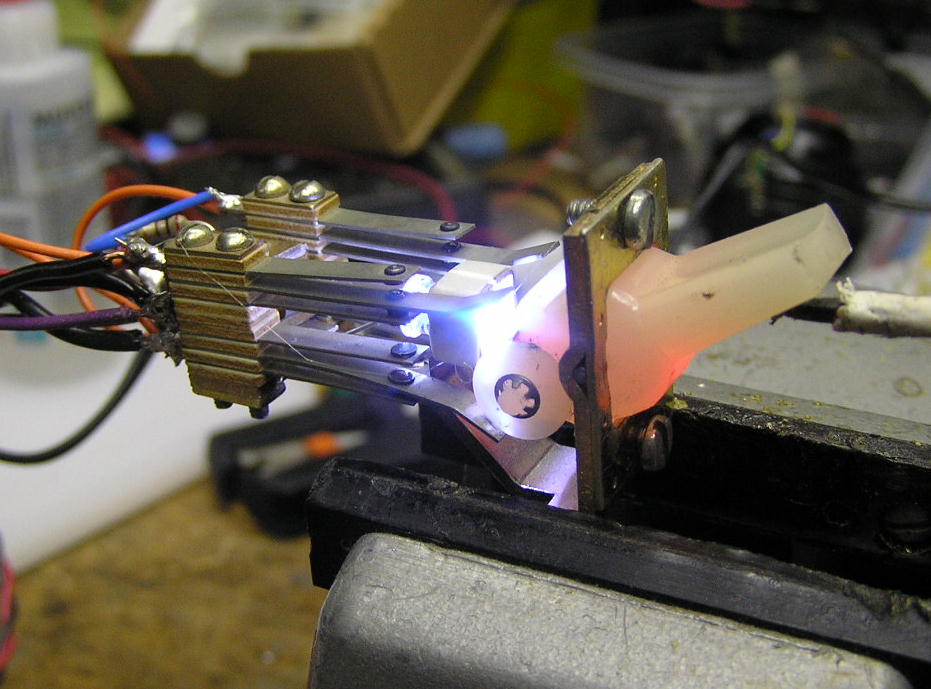

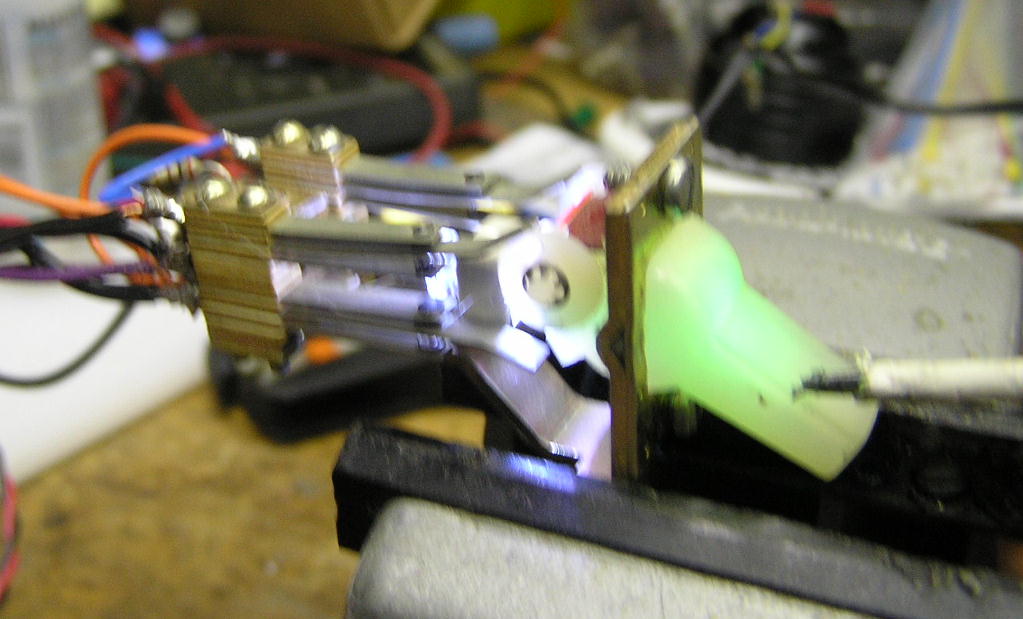

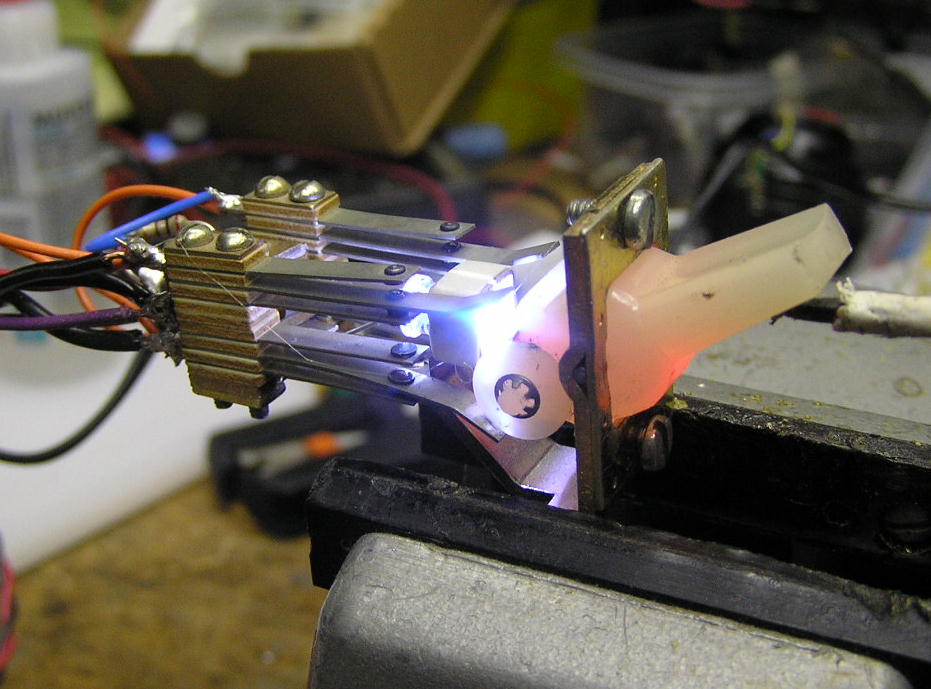

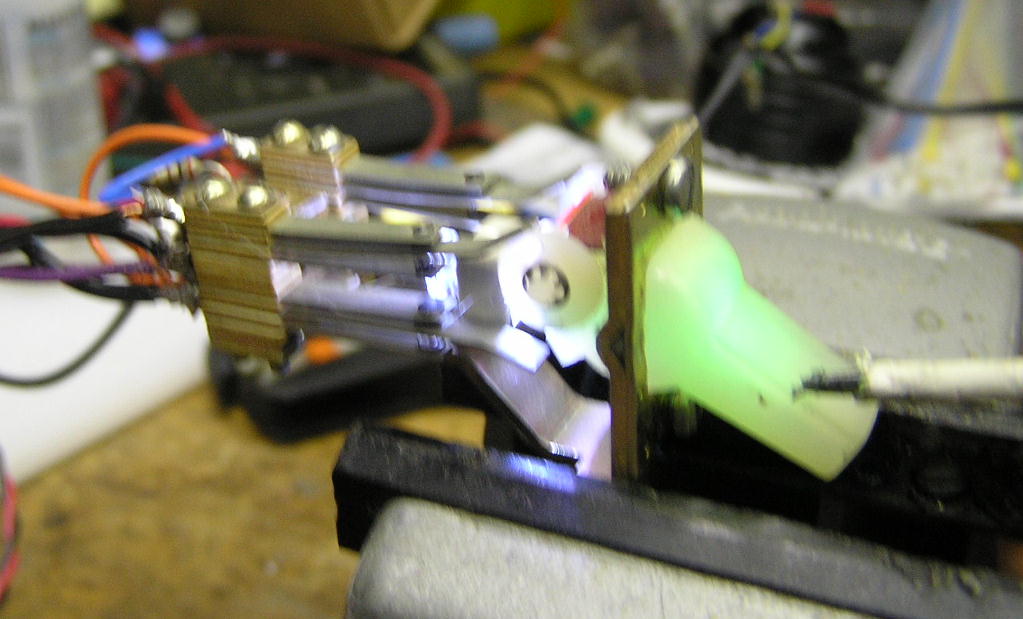

The circuit is quite simple; change the polarity on the voltage applied to the motor (6VDC) to change direction. There is also a simple 2-lead / 2- color (red/green) LED to show volume up (green) or down (red) on the unit itself. The motor appears to have a slip clutch in it so that if power is applied when it is at the limit current draw doesn't go up and there is no apparent damage.

The wired switch I'm temporarily using has a filter setup so that as you move the lever it is either red or green. I know it's a unique switch but any center off, momentary contact DPDT switch should suffice. I still need to enclose the switch still.

This can be inserted in a tape loop or in place of the pre out / main amp in jumpers found on many vintage receivers.

JimB

So here is this weekends project, a remote motorized volume control. Out of pocket costs - zero. All parts were lying around here and / or salvaged from junk units.

I removed the motorized volume control from a defunct Sony CD changer along with the 4 RCA connectors. Currently the remote is wired but I'm ordering a 2 channel RF remote from an ebay seller (~$18 shipped) to complete the project.

The circuit is quite simple; change the polarity on the voltage applied to the motor (6VDC) to change direction. There is also a simple 2-lead / 2- color (red/green) LED to show volume up (green) or down (red) on the unit itself. The motor appears to have a slip clutch in it so that if power is applied when it is at the limit current draw doesn't go up and there is no apparent damage.

The wired switch I'm temporarily using has a filter setup so that as you move the lever it is either red or green. I know it's a unique switch but any center off, momentary contact DPDT switch should suffice. I still need to enclose the switch still.

This can be inserted in a tape loop or in place of the pre out / main amp in jumpers found on many vintage receivers.

JimB