tmad40blue

"I can hear forever!"

Acoustic Research Potentiometer Restoration Guide

NOTE: I tend to take WAY TOO MANY photos. Sorry. :

:

INTRODUCTION

So you've picked up a pair of original Acoustic Research speakers. Congratulations! AR speakers are among the most cherished of the classic "east-coast" speakers of the 1960s and 1970s. Excited, you go to hook them up and - what's this? There's a surprising lack of high end... Hmm, maybe it's just that east-coast sound. Hopeful, you put your ear up to the tweeter and-- WHAT!? It's dead! There's no output. Frantic, you wonder what you're going to do about these dead tweeters that you just bought.

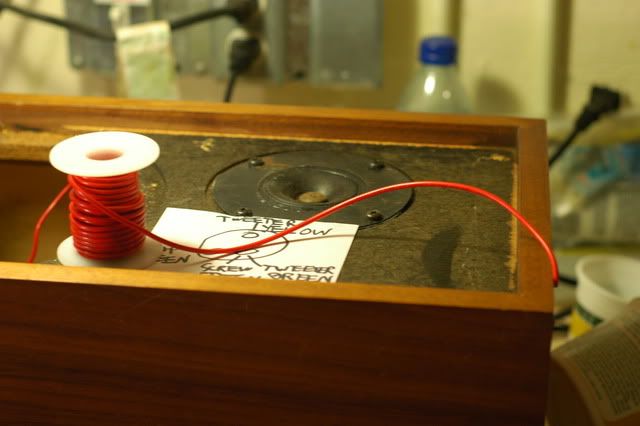

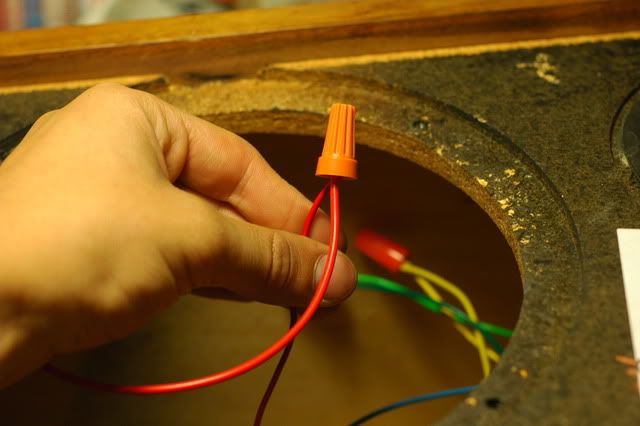

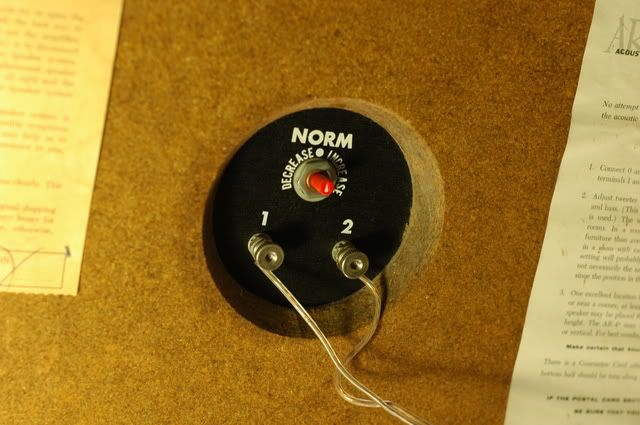

Fear not! There is a 90% chance that your tweeters are still very much alive and well. What has gone bad in your AR speakers are what are called the potentiometers. If you look on the back of the speaker, you will see a small knob that says "DECREASE - NORM - INCREASE". This is the potentiometer - it varies the tweeter's output level as you turn it. However, over the years, the potentiometer has corroded and can no longer carry an electric signal.

This is where you come in! Your job is now to open the speaker and clean the potentiometer and protect it from future corrosion. This guide will assist you, through the use of detailed explanation and helpful photos, to do just this, as well as a few other key items in any basic speaker restoration process. Let's get to work!

DISCLAIMER: The processes described in this guide are based on MY experiences, and MY experiences only. I realize that there are other methods by which to accomplish many of the things that I describe in this thread. I have described everything to the best of my ability. If you find that any process is not satisfactory for your standards, I am in no way stopping you from doing it your own way. However, following my guide will result in a good, listenable speaker.

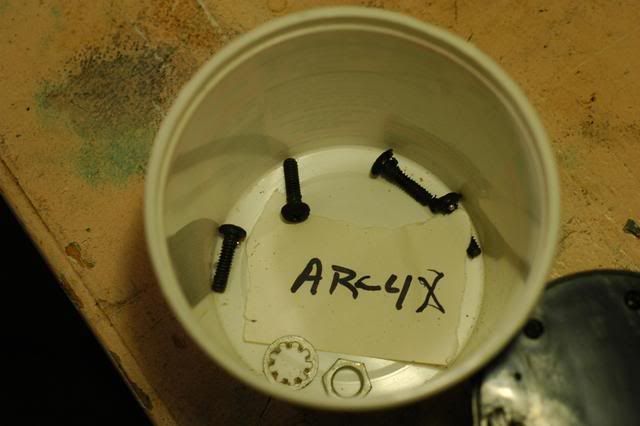

The information in this thread may be used as a general guide for the restoration of all classic AR speakers with potentiometers (including AR-2, AR-3, AR-4, etc). I am in no way responsible if you mess up your speakers because they are not exactly the same as the AR-4x that I based this thread on.

Acoustic Research Potentiometer Restoration

A Complete Moron's Guide, by tmad40blue

Table of Contents (clickable)

INTRODUCTION and TABLE OF CONTENTS (this post)

TOOLS OF THE TRADE

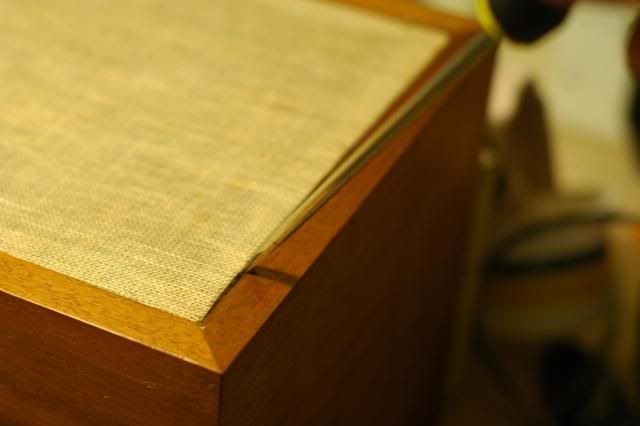

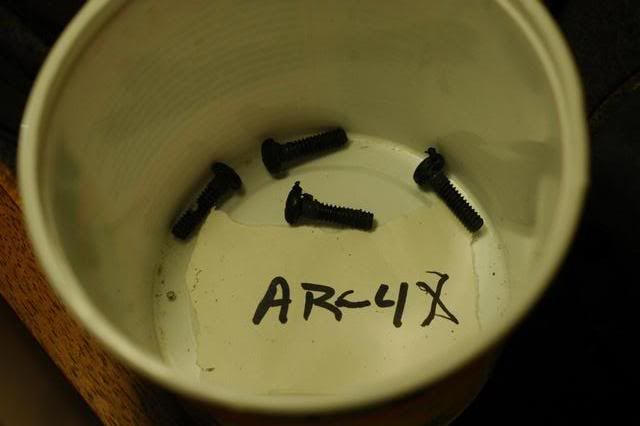

STEP ONE: Opening The Speaker

STEP TWO: Desolder The Woofer

STEP THREE: Unstuffing The Cabinet

STEP FOUR: Removing The Potentiometer

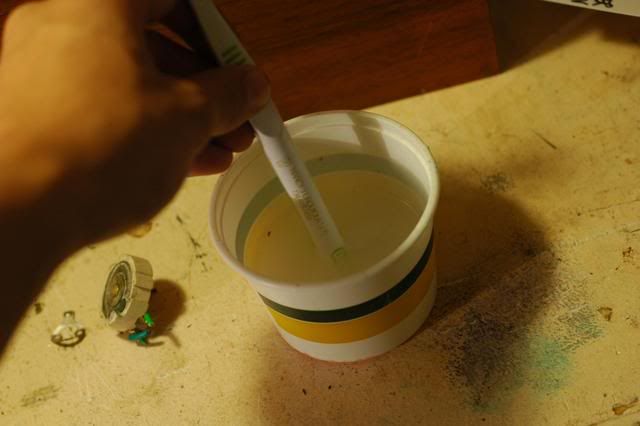

STEP FIVE: Cleaning The Potentiometer (part 1)

STEP SIX: Cleaning The Potentiometer (part 2)

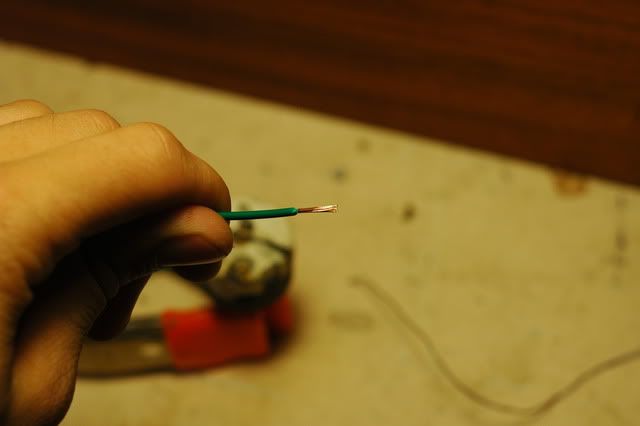

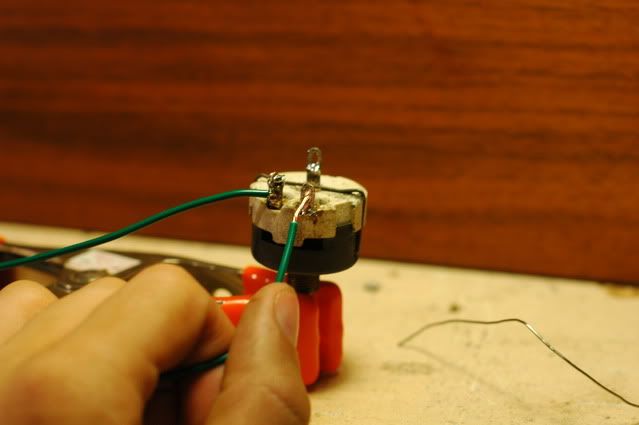

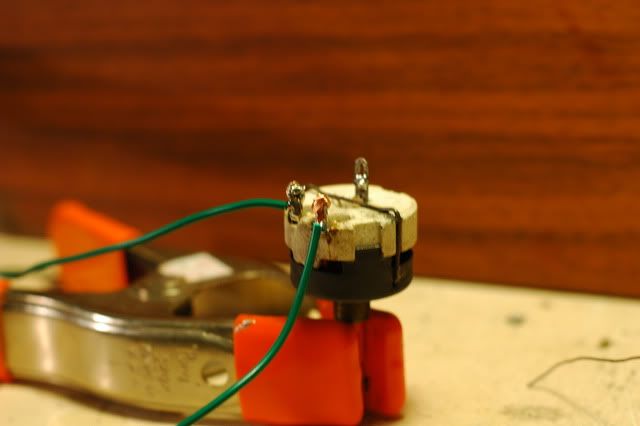

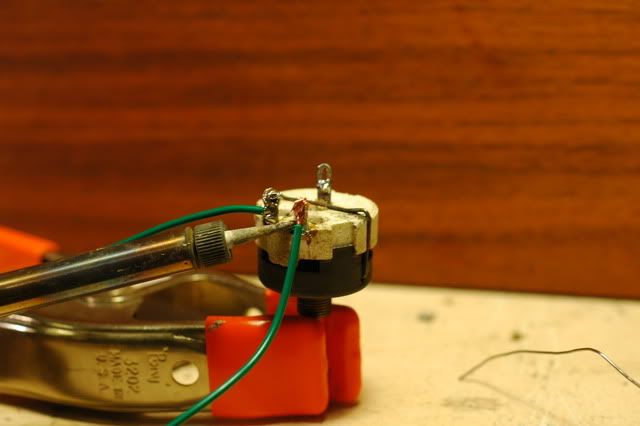

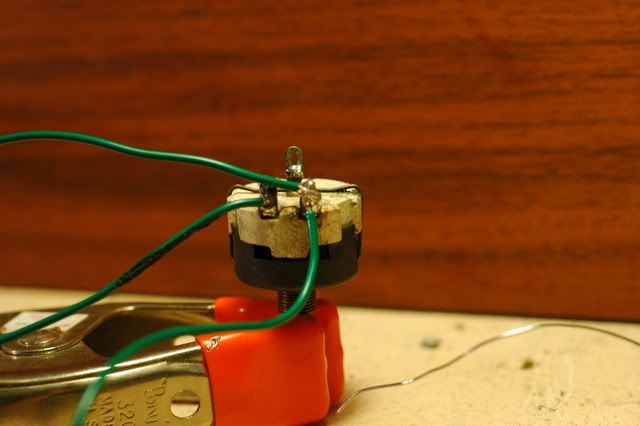

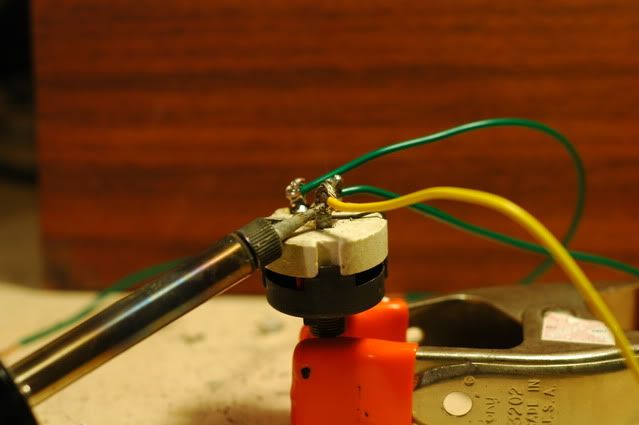

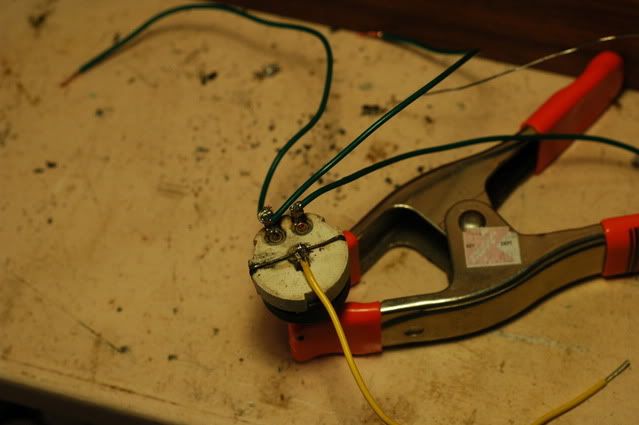

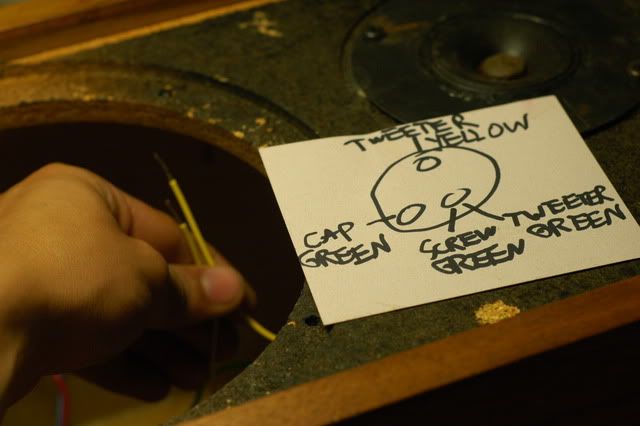

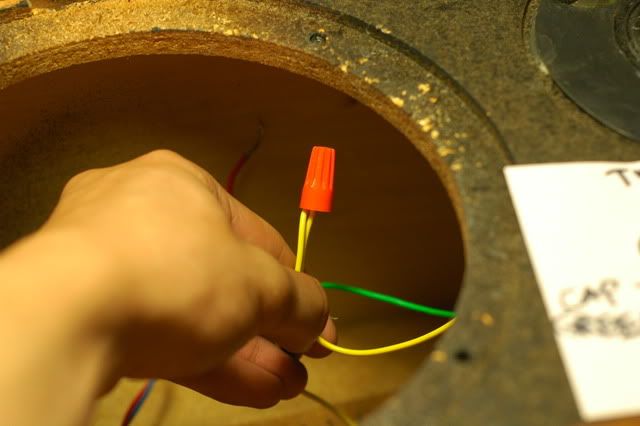

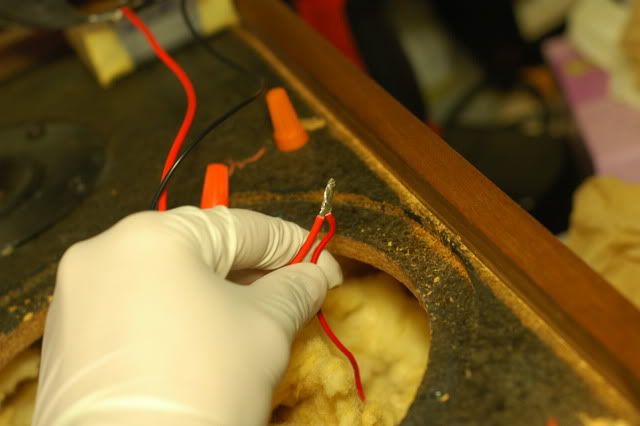

STEP SEVEN: Rewiring The Potentiometer (part 1)

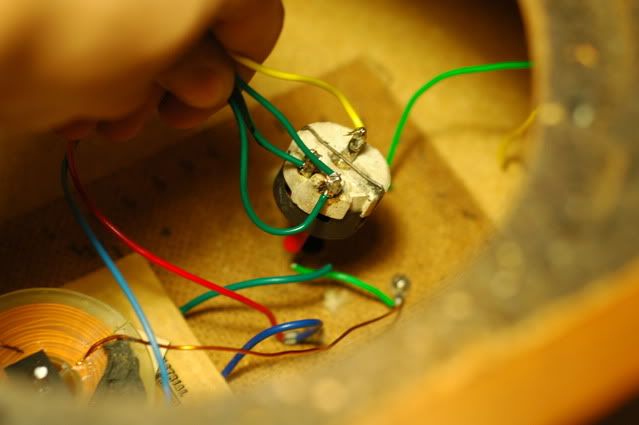

STEP EIGHT: Rewiring The Potentiometer (part 2)

STEP NINE: Rewiring The Crossover

STEP TEN: Rewiring The Woofer

STEP ELEVEN: Test The Speaker

STEP TWELVE: Restuff The Cabinet

STEP THIRTEEN: Reseal The Speaker

STEP FOURTEEN: Restore The Cabinet (optional)

CONCLUSION

Other informative posts

istariknight

gkimeng

WattUsay

dc270

RoyC

A Complete Moron's Guide, by tmad40blue

Table of Contents (clickable)

INTRODUCTION and TABLE OF CONTENTS (this post)

TOOLS OF THE TRADE

STEP ONE: Opening The Speaker

STEP TWO: Desolder The Woofer

STEP THREE: Unstuffing The Cabinet

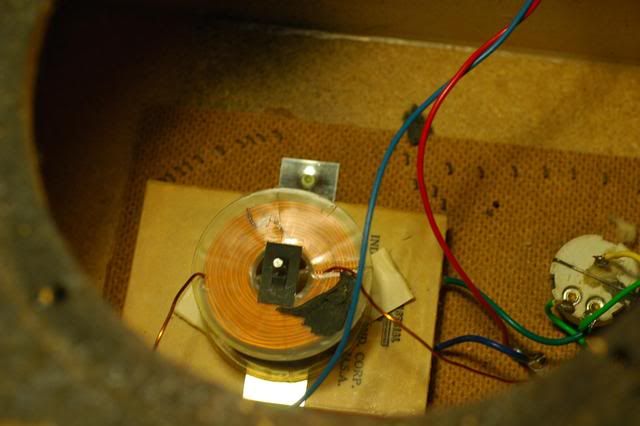

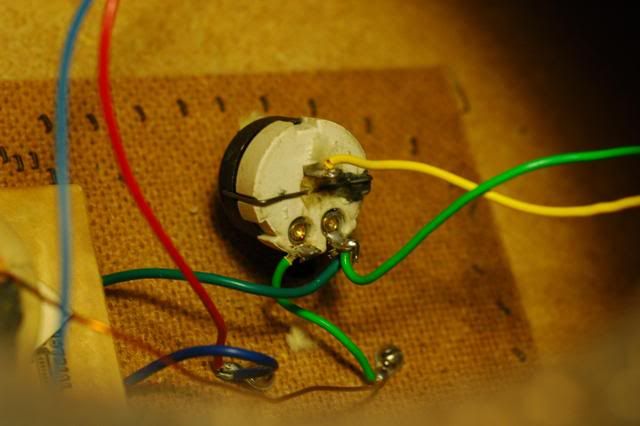

STEP FOUR: Removing The Potentiometer

STEP FIVE: Cleaning The Potentiometer (part 1)

STEP SIX: Cleaning The Potentiometer (part 2)

STEP SEVEN: Rewiring The Potentiometer (part 1)

STEP EIGHT: Rewiring The Potentiometer (part 2)

STEP NINE: Rewiring The Crossover

STEP TEN: Rewiring The Woofer

STEP ELEVEN: Test The Speaker

STEP TWELVE: Restuff The Cabinet

STEP THIRTEEN: Reseal The Speaker

STEP FOURTEEN: Restore The Cabinet (optional)

CONCLUSION

Other informative posts

istariknight

gkimeng

WattUsay

dc270

RoyC

NOTE: I tend to take WAY TOO MANY photos. Sorry.

INTRODUCTION

So you've picked up a pair of original Acoustic Research speakers. Congratulations! AR speakers are among the most cherished of the classic "east-coast" speakers of the 1960s and 1970s. Excited, you go to hook them up and - what's this? There's a surprising lack of high end... Hmm, maybe it's just that east-coast sound. Hopeful, you put your ear up to the tweeter and-- WHAT!? It's dead! There's no output. Frantic, you wonder what you're going to do about these dead tweeters that you just bought.

Fear not! There is a 90% chance that your tweeters are still very much alive and well. What has gone bad in your AR speakers are what are called the potentiometers. If you look on the back of the speaker, you will see a small knob that says "DECREASE - NORM - INCREASE". This is the potentiometer - it varies the tweeter's output level as you turn it. However, over the years, the potentiometer has corroded and can no longer carry an electric signal.

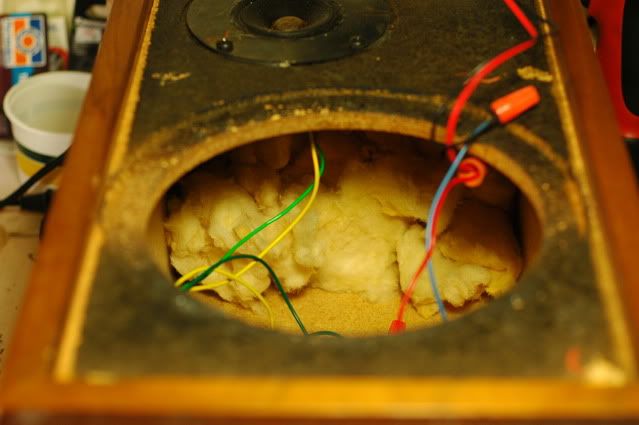

This is where you come in! Your job is now to open the speaker and clean the potentiometer and protect it from future corrosion. This guide will assist you, through the use of detailed explanation and helpful photos, to do just this, as well as a few other key items in any basic speaker restoration process. Let's get to work!

DISCLAIMER: The processes described in this guide are based on MY experiences, and MY experiences only. I realize that there are other methods by which to accomplish many of the things that I describe in this thread. I have described everything to the best of my ability. If you find that any process is not satisfactory for your standards, I am in no way stopping you from doing it your own way. However, following my guide will result in a good, listenable speaker.

The information in this thread may be used as a general guide for the restoration of all classic AR speakers with potentiometers (including AR-2, AR-3, AR-4, etc). I am in no way responsible if you mess up your speakers because they are not exactly the same as the AR-4x that I based this thread on.

Last edited: